ʻO ka māmā māmā o nā kaʻa he pahuhopu like ia o ka ʻoihana kaʻa honua. ʻO ka hoʻonui ʻana i ka hoʻohana ʻana i nā mea alumini alumini i nā ʻāpana automotive ke kuhikuhi o ka hoʻomohala ʻana no nā kaʻa ʻano hou. ʻO 6082 alumini alumini he mea hoʻomaʻamaʻa wela, hoʻoikaika i ka alumini alumini me ka ikaika haʻahaʻa, ka maikaʻi o ke ʻano, weldability, ka luhi luhi, a me ka pale ʻana i ka corrosion. Hiki ke hoʻokuʻu ʻia kēia alloy i loko o nā paipu, nā koʻokoʻo, a me nā profiles, a hoʻohana nui ʻia i nā ʻāpana kaʻa, nā ʻāpana welded structural, ka lawe ʻana, a me ka ʻoihana kūkulu.

I kēia manawa, ua palena ka noiʻi ʻana ma 6082 alumini alumini no ka hoʻohana ʻana i nā kaʻa ikehu hou ma Kina. No laila, ke noiʻi nei kēia haʻawina hoʻokolohua i nā hopena o ka 6082 aluminika mea hoʻoheheʻe ʻana i nā mea kikoʻī, nā ʻāpana kaʻina extrusion, nā ʻano quenching, a me nā mea ʻē aʻe, ma ka hana o ka profile alloy a me ka microstructure. Ke manaʻo nei kēia noiʻi e hoʻopaʻa pono i ka haku mele a me ka hana ʻana i nā ʻāpana e hana i nā mea alumini alumini 6082 kūpono no nā kaʻa ikehu hou.

1. Nā mea ho'āʻo a me nā ʻano hana

Ke kahe kaʻina hana hoʻokolohua: Lakiō haku mele Alloy - Hoʻoheheʻe Ingot - homogenization Ingot - Ke ʻoki ʻana i loko o nā bilets - Extrusion o nā kiʻi - Ke kinai ʻana i nā profiles - ʻO ka ʻelemakule artificial - Ka hoʻomākaukau ʻana i nā specimens hoʻāʻo.

1.1 Hoʻomākaukau Ingot

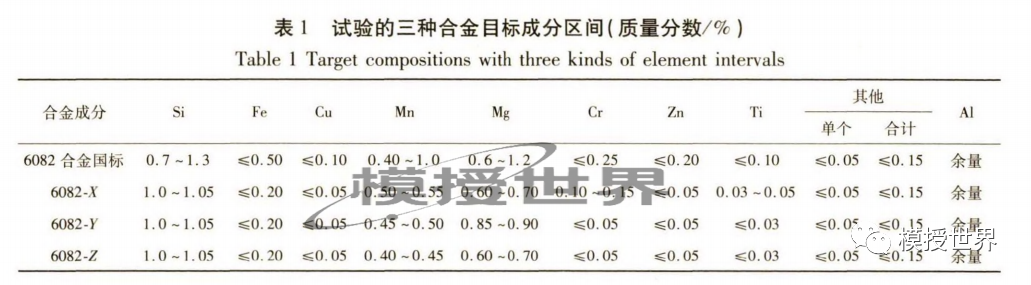

I loko o ke ao holoʻokoʻa o 6082 alumini alumini haku mele, ʻekolu mele i koho ʻia me nā pae mana haiki, i kapa ʻia ʻo 6082-/6082″, 6082-Z, me ka ʻike like ʻole Si. Mg element maʻiʻo, y > z; Mn mea maʻiʻo, x > y > z; Cr, maʻiʻo ʻeleʻele Ti, x > y = z. Hōʻike ʻia nā koina paʻa o ka hui ʻana o ka alloy ma ka Papa 1. Ua hana ʻia ka hoʻolei ʻana i ka Ingot me ka hoʻohana ʻana i ke ʻano hoʻoheheʻe wai-hoʻomau semi-continuous, a ukali ʻia e ka mālama homogenization. Hoʻohui like ʻia nā ʻano ʻekolu a pau me ka hoʻohana ʻana i ka ʻōnaehana hoʻokumu o ka hale hana ma 560 ° C no 2 mau hola me ka hoʻoluʻu wai.

1.2 Extrusion o na Profile

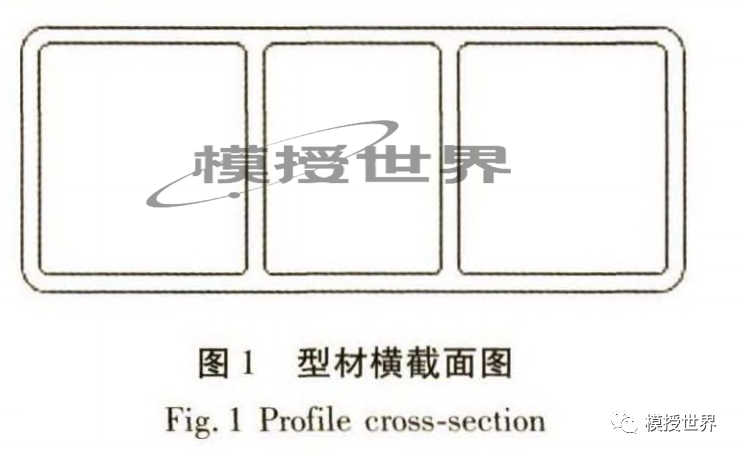

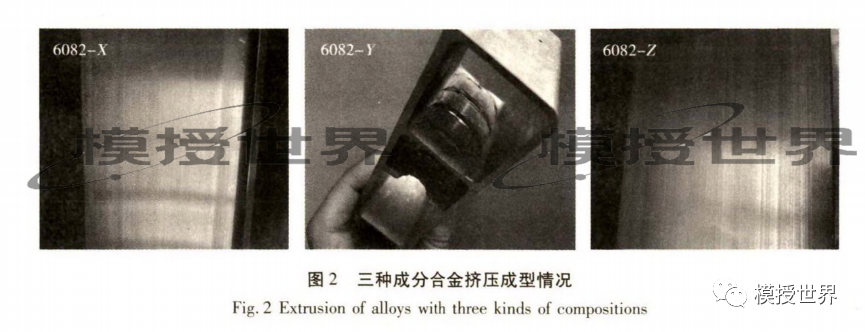

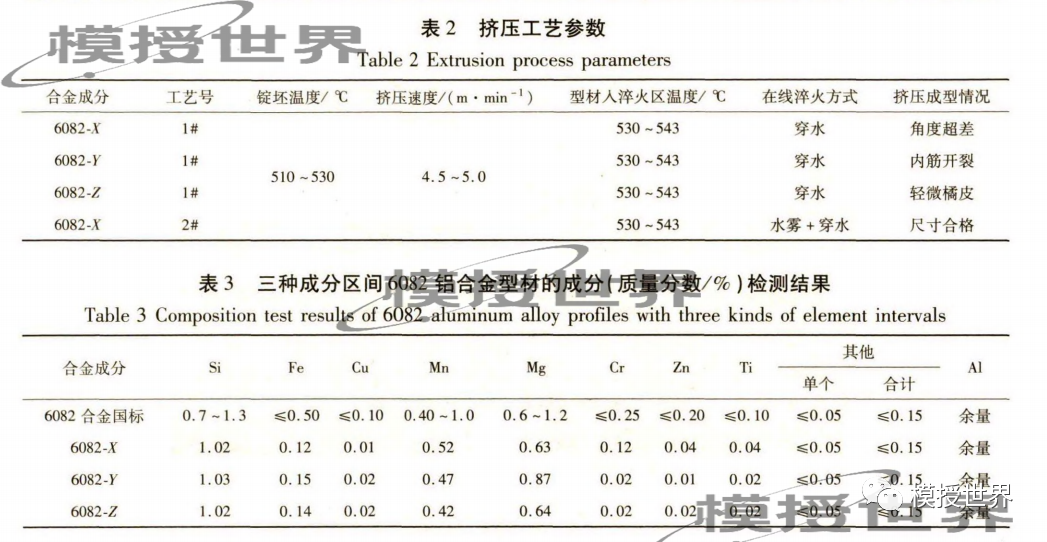

Ua hoʻoponopono pono ʻia nā ʻāpana kaʻina hana extrusion no ka wela hoʻomehana billet a me ka wikiwiki hoʻoluʻu ʻana. Hōʻike ʻia ka ʻāpana keʻa o nā profile extruded ma ke kiʻi 1. Hōʻike ʻia nā ʻāpana kaʻina extrusion ma ka Papa 2. Hōʻike ʻia ke kūlana hoʻokumu o nā profile extruded ma ka Figure 2.

2. Nā hopena ho'āʻo a me ka nānā ʻana

Ua hoʻoholo ʻia ka haku mele ʻana o nā 6082 alumini alumini i loko o nā pae haku mele me ka hoʻohana ʻana i kahi spectrometer heluhelu pololei Swiss ARL, e like me ka hōʻike ʻana ma ka Papa 3.

2.1 Hoao Hana

No ka hoʻohālikelike ʻana, ua nānā ʻia ka hana ʻana o nā ʻano hoʻohui hui like ʻole me nā ʻano hoʻoheheʻe like ʻole, nā ʻāpana extrusion like, a me nā kaʻina hana kahiko.

2.1.1 Hana Hana

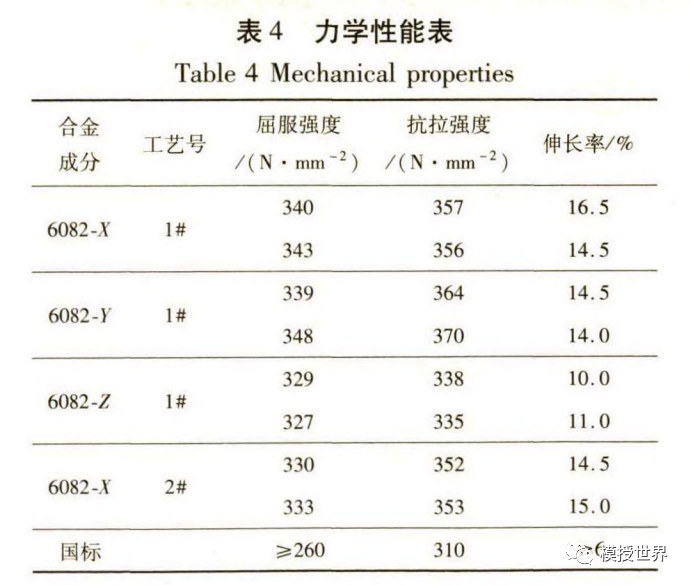

Ma hope o ka ʻelemakule kahiko ma 175 ° C no 8 mau hola, ua lawe ʻia nā specimens maʻamau mai ke kuhikuhi o ka extrusion o nā profiles no ka hoʻāʻo tensile e hoʻohana ana i kahi mīkini hoʻāʻo uila uila Shimadzu AG-X100. Hōʻike ʻia ka hana mechanical ma hope o ka ʻelemakule artificial no nā haku mele like ʻole a me nā ʻano hana hoʻopau ʻana ma ka Papa 4.

Mai ka Papa 4, hiki ke ʻike ʻia ua ʻoi aku ka hana mechanical o nā profiles a pau ma mua o nā kumu waiwai maʻamau. ʻO nā kiʻi i hana ʻia mai 6082-Z alloy billets i emi iho ka elongation ma hope o ka haki ʻana. ʻO nā kiʻi i hana ʻia mai 6082-7 alloy billets i loaʻa ka hana mechanical kiʻekiʻe loa. 6082-X nā profiles alloy, me nā ʻano hoʻonā paʻa like ʻole, hōʻike i ka hana kiʻekiʻe me nā ʻano hoʻoheheʻe wikiwiki.

2.1.2 Ke ho'āʻo ʻana i ka hana ʻana

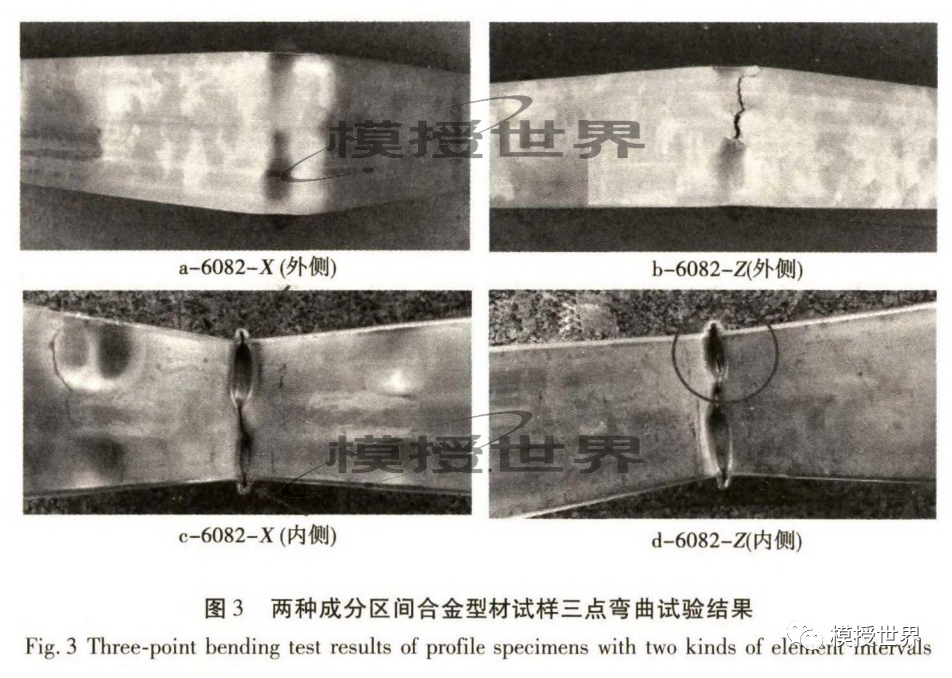

Ma ka hoʻohana ʻana i ka mīkini hoʻāʻo honua uila, ua mālama ʻia nā hoʻāʻo kulou ʻekolu ma luna o nā laʻana, a ua hōʻike ʻia nā hopena kulou ma ke Kiʻi 3. Hōʻike ka Figure 3 i nā huahana i hana ʻia mai 6082-Z alloy billets i loaʻa i ka ʻili ʻalani koʻikoʻi ma luna o ka ʻili a nahā ma ke kua o nā laʻana i piko. ʻOi aku ka maikaʻi o ka piʻo ʻana o nā huahana mai ka 6082-X alloy billets, nā ʻili laulima ʻole me ka ʻili ʻalani, a me nā māwae liʻiliʻi wale nō ma nā kūlana i kaupalena ʻia e nā kūlana geometric ma ke kua o nā laʻana i piʻo.

2.1.3 Nānā Hoʻonui Kiʻekiʻe

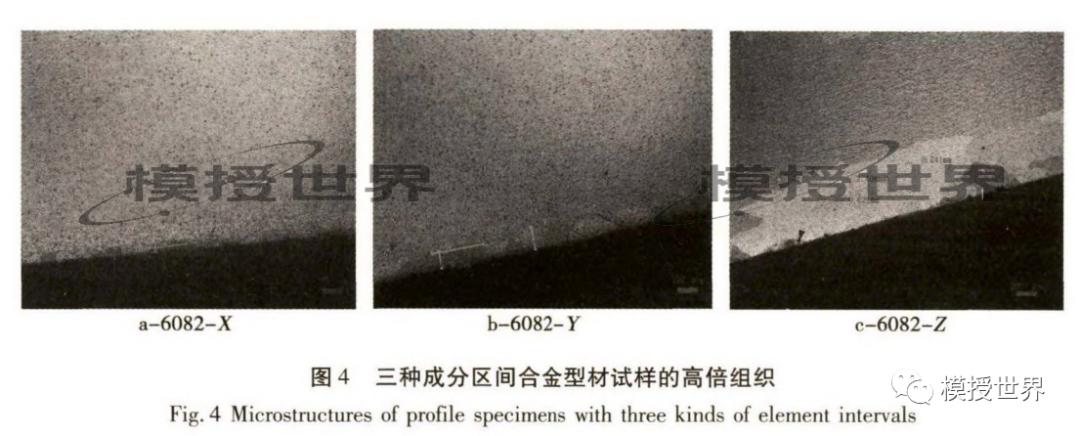

Ua nānā ʻia nā laʻana ma lalo o kahi microscope optical Carl Zeiss AX10 no ka nānā ʻana i ka microstructure. Hōʻike ʻia nā hualoaʻa o ka ʻikena microstructure no nā ʻaoʻao ʻekolu huila huila ma ke Kiʻi 4. Hōʻike ka Figure 4 i ka nui o nā huahana i hana ʻia mai ka 6082-X rod a me 6082-K alloy billets, me ka ʻoi aʻe o ka nui o ka palaoa ma 6082-X alloy i hoʻohālikelike ʻia me 6082-y alloy. ʻO nā huahana i hana ʻia mai 6082-Z alloy billets i ʻoi aku ka nui o ka palaoa a me nā ʻāpana cortex mānoanoa, i ʻoi aku ka maʻalahi o ka ʻili ʻalani a hoʻonāwaliwali i ka paʻa metala kūloko.

2.2 Nānā Hua

Ma muli o nā hopena ho'āʻo i luna, hiki ke hoʻoholo ʻia e pili ana ka hoʻolālā ʻana o ka hoʻohuihui alloy i ka microstructure, ka hana, a me ka formability o nā profile extruded. ʻO ka hoʻonui ʻia ʻana o ka mea Mg e hōʻemi ana i ka palaki alloy a alakaʻi i ka hana ʻana i ka wā extrusion. He hopena maikaʻi ko Mn kiʻekiʻe, Cr, a me Ti i ka hoʻomaʻemaʻe ʻana i ka microstructure, ʻo ia hoʻi ka hopena maikaʻi i ka maikaʻi o ka ʻili, ka hana kulou, a me ka hana holoʻokoʻa.

3. Ka hopena

Hoʻopilikia nui ka mea Mg i ka hana mechanical o 6082 alumini alumini. ʻO ka maʻiʻo Mg i hoʻonui ʻia e hōʻemi i ka plasticity alloy a alakaʻi i ka hana ʻana i ka wā extrusion.

He hopena maikaʻi ʻo Mn, Cr, a me Ti i ka hoʻomaʻemaʻe microstructure, e alakaʻi ana i ka hoʻomaikaʻi ʻana i ka maikaʻi o ka ʻili a me ka hana ʻana o nā huahana extruded.

Loaʻa ka hopena ʻike ʻia i ka hana ʻana o 6082 alumini alloy profiles nā ʻokoʻa hoʻomaha hoʻomaha. No ka hoʻohana ʻana i nā kaʻa, ʻoi aku ka maikaʻi o ka hana ʻana i ka mīkini a hōʻoia i ke ʻano o nā profiles a me ka pololei o ke ana.

Hoʻoponopono ʻia e May Jiang mai MAT Aluminum

Ka manawa hoʻouna: Mar-26-2024