1.Hoʻolauna

Hōʻike nā alumini alumini me ka ikaika liʻiliʻi i nā hiʻohiʻona kaʻina hana maikaʻi, ka hoʻopau ʻana i ka naʻau, ka paʻakikī o ka hopena, a me ka pale ʻana i ka corrosion. Hoʻohana nui ʻia lākou i nā ʻoihana like ʻole, e like me ka uila a me ke kai, no ka hana ʻana i nā paipu, nā koʻokoʻo, nā profiles, a me nā uea. I kēia manawa, ke hoʻonui nei ka noi no 6082 mau pahu alumini alumini. No ka hoʻokō ʻana i nā koi o ka mākeke a me nā koi o ka mea hoʻohana, ua hana mākou i nā hoʻokolohua ma nā kaʻina hoʻomehana extrusion ʻokoʻa a me nā kaʻina hana wela hope no nā pahu 6082-T6. ʻO kā mākou pahuhopu ʻo ia ka ʻike ʻana i kahi ʻano hoʻomaʻamaʻa wela e hoʻokō i nā koi hana mechanical no kēia mau kaola.

2. Nā mea hoʻokolohua a me ka holo kaʻina hana

2.1 Mea Ho'āʻo

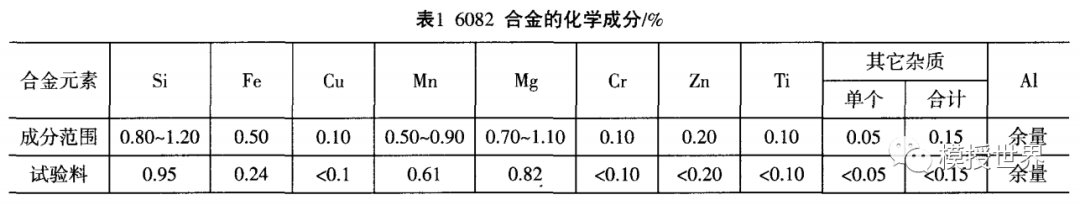

ʻO ka hoʻolei ʻana i nā ingots o ka nui Ф162 × 500 i hana ʻia me ka hoʻohana ʻana i ke ʻano hoʻoheheʻe semi-continuous a hoʻokau ʻia i ka mālama like ʻole. ʻO ka maikaʻi metallurgical o nā ingots i hoʻokō me nā kūlana ʻenehana hoʻokele kūloko o ka ʻoihana. Hōʻike ʻia ka haku mele ʻana o ka huila 6082 ma ka Papa 1.

2.2 Ke Kaʻina Hana Hana Hana

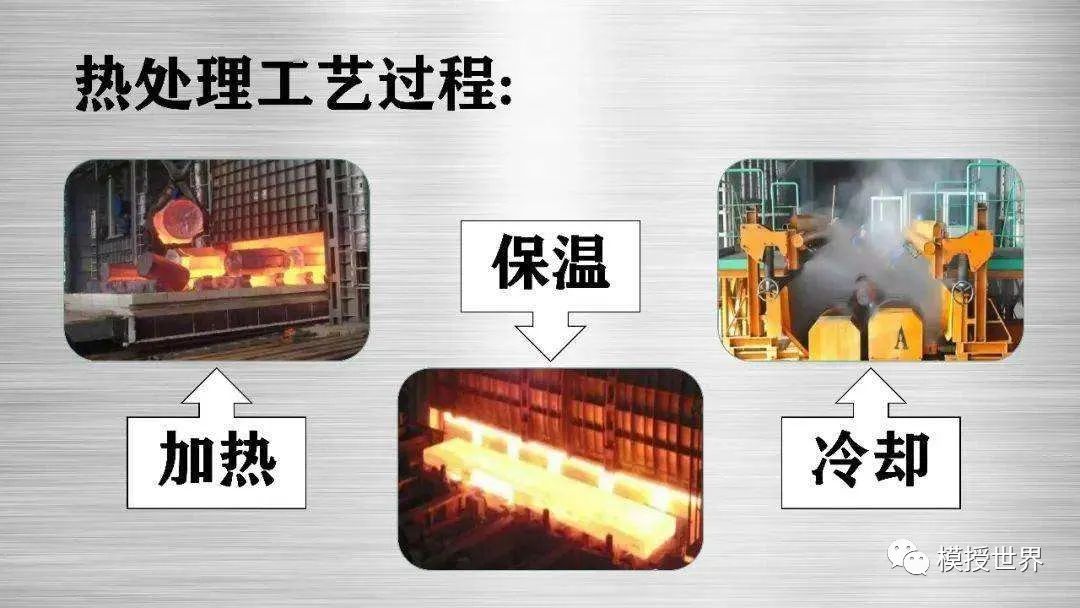

ʻO nā pahu hoʻokolohua 6082 he kikoʻī o Ф14mm. ʻO ka pahu extrusion he anawaena o Ф170mm me kahi hoʻolālā extrusion 4-hole a me kahi coefficient extrusion o 18.5. ʻO ke kahe kaʻina kikoʻī e pili ana i ka hoʻomehana ʻana i ka ingot, extrusion, quenching, stretching straightening and sampling, roller straightening, final cutting, artificial aging, quality inspection, and delivery.

3. Nā Pahuhopu Hoʻokolohua

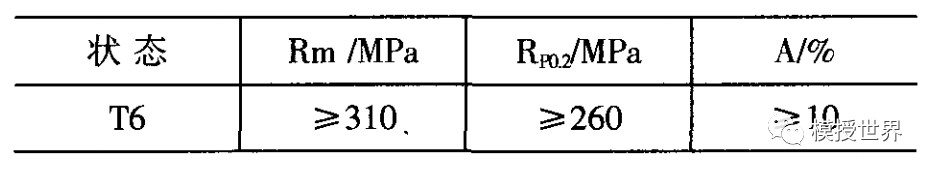

ʻO ka pahuhopu o kēia noiʻi ʻana ʻo ia ka ʻike ʻana i nā ʻāpana kaʻina hana hoʻōla wela extrusion a me nā ʻāpana lapaʻau wela hope e hoʻoikaika i ka hana o nā pahu 6082-T6, i ka loaʻa ʻana o nā koi hana maʻamau. Wahi a nā kūlana, pono e hoʻokō nā waiwai mechanical longitudinal o ka 6082 alloy i nā kikoʻī i helu ʻia ma ka Papa 2.

4.Hoʻokolohua Hoʻokolohua

4.1 Extrusion Heat Treatment Investigation

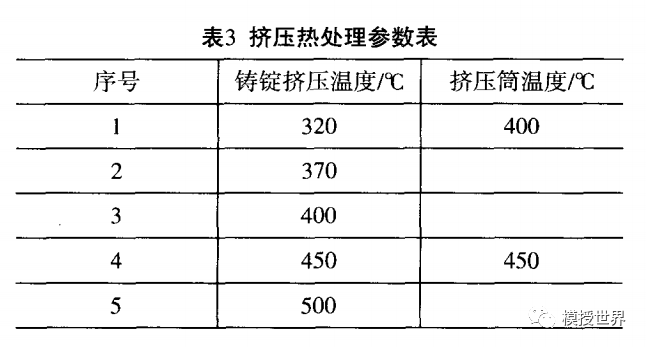

ʻO ka hoʻokolokolo hoʻomaʻamaʻa wela extrusion i kālele nui ʻia i nā hopena o ka hoʻolei ʻana i ka mahana extrusion ingot a me ka wela pahu extrusion ma nā waiwai mechanical. Hōʻike ʻia nā koho koho kikoʻī ma ka Papa 3.

4.2 Hoʻonā Paʻa a me ka ʻImi Hoʻomaʻamaʻa Wela ʻelemakule

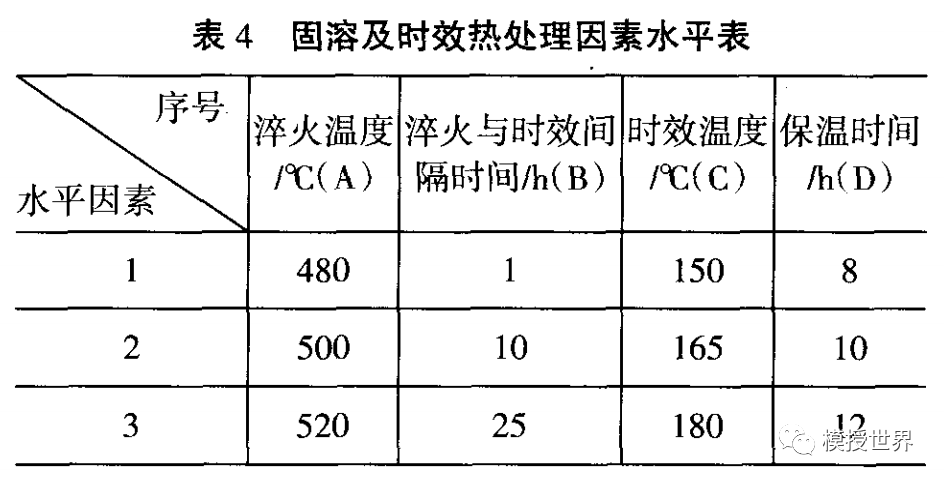

Ua hoʻohana ʻia kahi hoʻolālā hoʻokolohua orthogonal no ka hoʻonā paʻa a me ke kaʻina lapaʻau wela kahiko. Hāʻawi ʻia nā pae kumu i koho ʻia ma ka Papa 4, me ka papa hoʻolālā orthogonal i kapa ʻia ʻo IJ9(34).

5. Nā hopena a me ka nānā ʻana

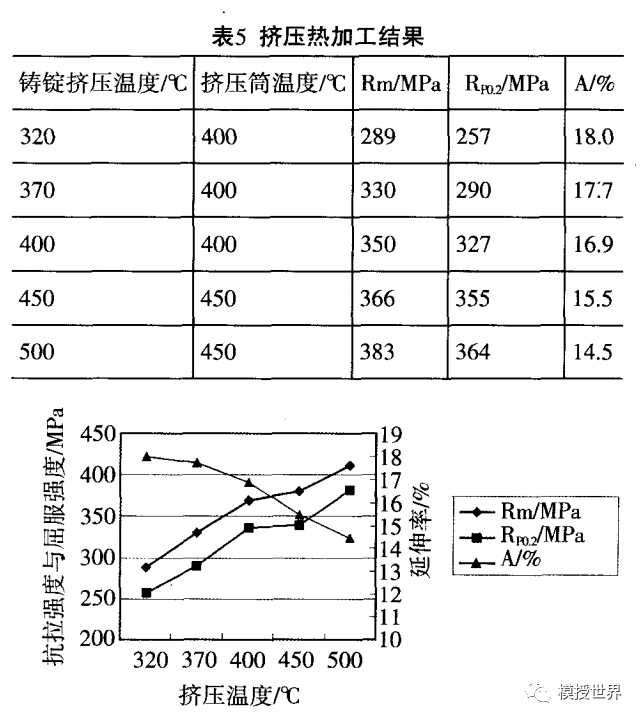

5.1 Nā hualoaʻa a me ka nānā ʻana o ka Extrusion Heat Treatment Experiment Extrusion

Hōʻike ʻia nā hopena o nā hoʻokolohua extrusion wela ma ka Papa 5 a me ka Figure 1. Ua lawe ʻia ʻeiwa mau laʻana no kēlā me kēia hui, a ua hoʻoholo ʻia kā lākou mau ʻawelika hana mechanical. Ma muli o ka loiloi metallographic a me ka haku mele ʻana, ua hoʻokumu ʻia kahi regimen mālama wela: hoʻopau ʻia ma 520 ° C no 40 mau minuke a ʻelemakule ma 165 ° C no 12 mau hola. Mai ka Papa 5 a me ka Helu 1, hiki ke ike ia e like me ka hoolei ana o ka ingot extrusion ana wela a me ka extrusion ipu wela ua pii malie ka tensile ikaika a me ka hua ikaika. Loaʻa nā hopena maikaʻi loa ma nā mahana extrusion o 450-500 ° C a me kahi mahana pahu extrusion o 450 ° C, i hoʻokō i nā koi maʻamau. ʻO kēia ma muli o ka hopena o ka paʻakikī o ka hana anu i nā wela extrusion haʻahaʻa, e hōʻeha ana i ka palena o ka palaoa a me ka hoʻonui ʻana i ka decomposition paʻa paʻa ma waena o A1 a me Mn i ka wā hoʻomehana ma mua o ke kinai ʻana, e alakaʻi ana i ka recrystallization. I ka piʻi ʻana o ka mahana extrusion, ʻoi aku ka maikaʻi o ka ikaika loa Rm o ka huahana. Ke hoʻokokoke a ʻoi aku ka mahana o ka pahu extrusion i ka mahana ingot, ua emi ka deformation ʻole, e hōʻemi ana i ka hohonu o nā apo palaoa a hoʻonui i ka ikaika hua Rm. No laila, ʻo nā ʻāpana kūpono no ka mālama ʻana i ka wela extrusion: ʻo ka mahana extrusion ingot o 450-500 ° C a me ka mahana pahu extrusion o 430-450 ° C.

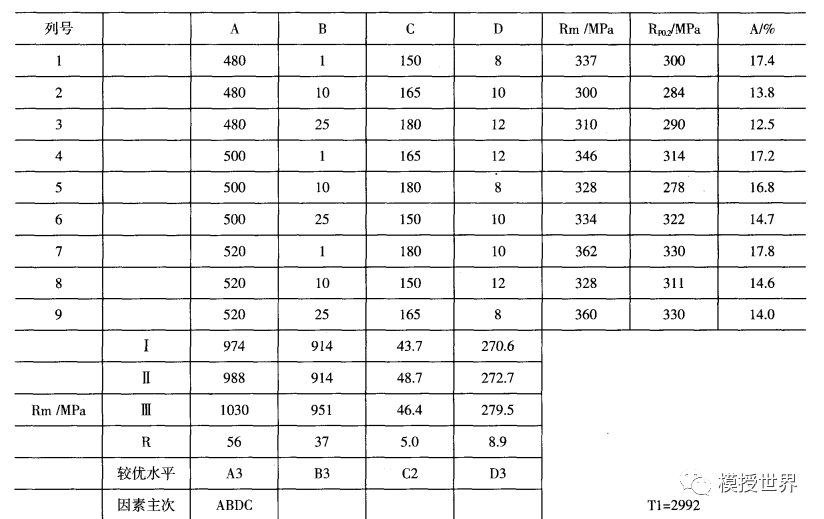

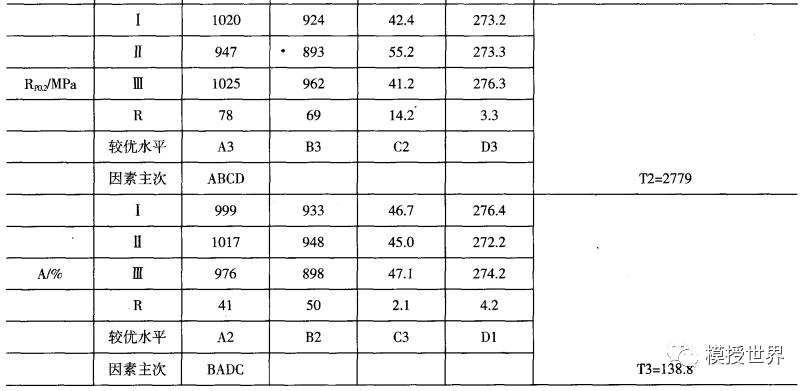

5.2 Hoʻonā Paʻa a me nā hopena hoʻokolohua Orthogonal kahiko a me ka nānā ʻana

Hōʻike ka papa 6 ʻo nā pae maikaʻi loa ʻo A3B1C2D3, me ke kinai ʻana ma 520 ° C, ka mahana kahiko kūlohelohe ma waena o 165-170 ° C, a me ka lōʻihi o ka wā kahiko o 12 mau hola, e hopena i ka ikaika kiʻekiʻe a me ka plasticity o nā kaola. Hoʻokumu ke kaʻina hoʻopaʻa i ka hopena paʻa supersaturated. I ka haʻahaʻa haʻahaʻa quenching wela, ka hoʻohaʻahaʻa ʻana o ka supersaturated solid solution e emi iho ana, e pili ana i ka ikaika. ʻO kahi mahana hoʻopiʻi ma kahi o 520 ° C e hoʻonui nui i ka hopena o ka hoʻoikaika paʻa paʻa i hoʻoiho ʻia. ʻO ka wā ma waena o ke kinai ʻana a me ka ʻelemakule hana, ʻo ia hoʻi, ka mālama ʻana i ka mahana o ka lumi, e hoʻopili nui i nā waiwai mechanical. Hoʻopuka nui ʻia kēia no nā koʻokoʻo ʻaʻole i kikoo ma hope o ke kinai ʻana. Ke ʻoi aku ka manawa ma waena o ka hoʻopau ʻana a me ka ʻelemakule ma mua o 1 hola, ʻoi aku ka nui o ka ikaika, ʻoi aku ka ikaika o ka hāʻawi ʻana.

5.3 ʻIkepili Microstructure Metallographic

Ua mālama ʻia nā loiloi hoʻonui kiʻekiʻe a me ka polarized ma nā pahu 6082-T6 i nā mahana hoʻonā paʻa o 520 ° C a me 530 ° C. Hōʻike ʻia nā kiʻi hoʻonui kiʻekiʻe i ka ua hui pū ʻia me ka nui o nā ʻāpana precipitate i puʻunaue like ʻia. Ua hōʻike ʻia ka ʻokoʻa ʻokoʻa o nā kiʻi hoʻolālā ʻai polarized me ka hoʻohana ʻana i nā mea hana Axiovert200. Ua hōʻike ʻia ka ʻāpana waena i nā hua liʻiliʻi a me nā ʻano like ʻole, aʻo nā ʻaoʻao i hōʻike ʻia i kahi recrystallization me nā hua elongated. ʻO kēia ma muli o ka ulu ʻana o nā nuclei aniani i nā wela kiʻekiʻe, e hana ana i nā ʻokiʻoki like me ka nila.

6. Hoʻoponopono Hana Hana Hana

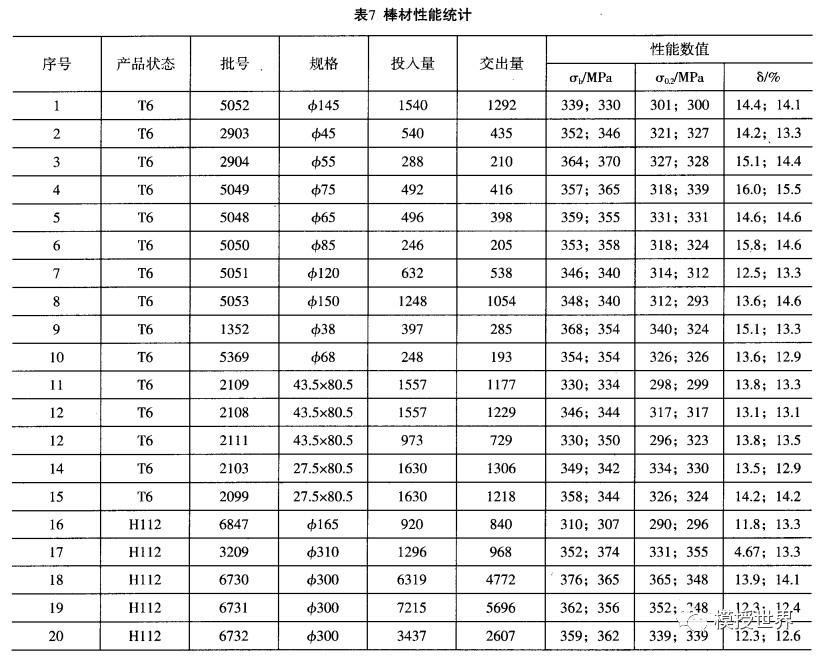

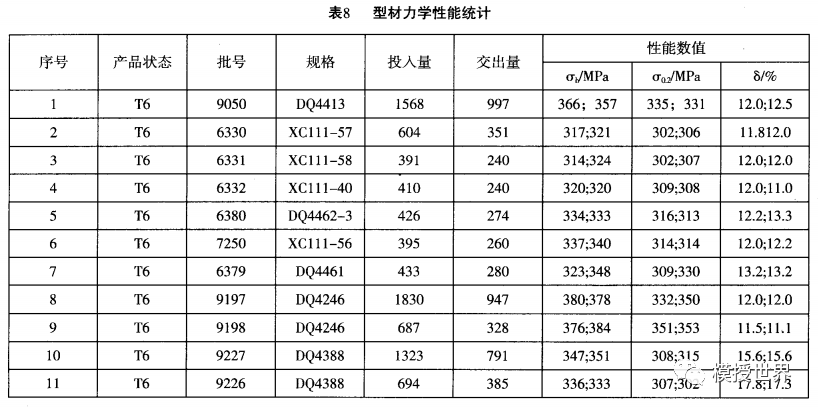

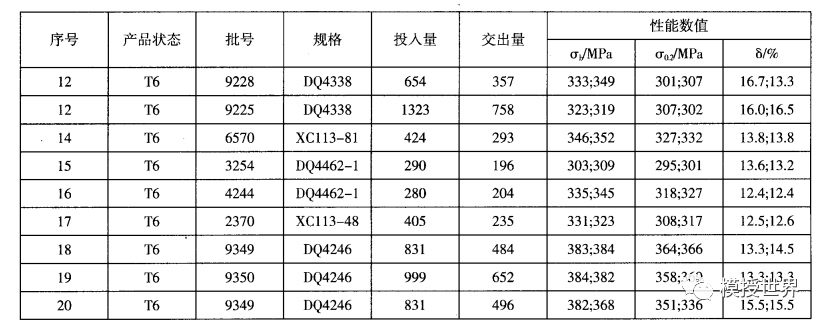

Ma ka hana maoli, ua alakaʻi ʻia nā ʻikepili hana mechanical ma 20 mau pahu pahu a me 20 mau pūʻulu profile. Hōʻike ʻia nā hopena ma ka Papa 7 a me 8. Ma ka hana maoli, ua hana ʻia kā mākou extrusion kaʻina hana i nā mahana i loaʻa i nā hōʻailona mokuʻāina T6, a ua hoʻokō ka hana mechanical i nā kumu waiwai.

7. Ka hopena

(1) Extrusion wela lapaʻau nā palena: Ingots extrusion mahana o 450-500°C; extrusion ipu wela o 430-450°C.

(2) Nā palena hoʻopaʻa wela hope loa: ʻO ka mahana wela paʻa maikaʻi loa o 520-530°C; ka mahana wela ma 165±5°C, ka lōʻihi o ka wā kahiko o 12 hola; ʻAʻole pono ka manawa ma waena o ka hoʻopau ʻana a me ka ʻelemakule ma mua o 1 hola.

(3) Ma muli o ka loiloi kūpono, ʻo ke kaʻina hana hoʻōla wela hiki ke loaʻa: extrusion wela o 450-530 ° C, extrusion pahu wela o 400-450 ° C; ʻO ka mahana hoʻonā paʻa o 510-520 ° C; ka hoʻomaʻamaʻa kahiko o 155-170 ° C no 12 mau hola; ʻaʻohe palena kikoʻī i ka wā ma waena o ke kinai ʻana a me ka ʻelemakule. Hiki ke hoʻokomo i kēia i loko o nā alakaʻi hana kaʻina hana.

Hoʻoponopono ʻia e May Jiang mai MAT Aluminum

Ka manawa hoʻouna: Mar-15-2024