Inā ʻaʻole like nā ʻano mechanical o extrusions e like me ka mea i manaʻo ʻia, ʻike pinepine ʻia ka nānā ʻana i ka haku mua o ka billet a i ʻole nā kūlana extrusion / ʻelemakule. He liʻiliʻi ka poʻe e nīnau inā he pilikia paha ka homogenization iā ia iho. ʻO ka ʻoiaʻiʻo, koʻikoʻi ka pae homogenization no ka hana ʻana i nā extrusions kiʻekiʻe. ʻO ka mālama pono ʻole ʻana i ka pae homogenization hiki ke alakaʻi i:

● Hoʻonui i ke kaomi ʻana

● ʻOi aku nā hemahema

●E hoʻokaʻawale i nā ʻano ma hope o ka anodizing

●Lower extrusion māmā holo

● ʻAʻohe ʻano mechanical

ʻElua kumu nui o ka pae homogenization: ka hoʻomaʻemaʻe ʻana i nā pūhui intermetallic i loko o ka hao, a me ka hāʻawi hou ʻana i ka magnesium (Mg) a me ke silikona (Si). Ma ka nānā ʻana i ka microstructure o ka billet ma mua a ma hope o ka homogenization, hiki i kekahi ke wānana inā e hana maikaʻi ka billet i ka wā extrusion.

Ka hopena o ka Homogenization Billet i ka Paʻa

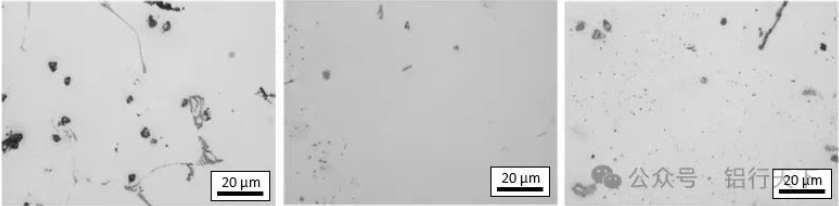

Ma 6XXX extrusions, hiki mai ka ikaika mai Mg- a me Si-rich phase i hana ʻia i ka wā ʻelemakule. ʻO ka hiki ke hana i kēia mau ʻāpana e pili ana i ka waiho ʻana i nā mea i loko o ka hopena paʻa ma mua o ka hoʻomaka ʻana o ka ʻelemakule. No ka lilo ʻana o Mg a me Si i ʻāpana o ka hopena paʻa, pono e kinai koke ʻia ka metala mai luna o 530 °C. Ma nā mahana ma luna o kēia wahi, hoʻoheheʻe maoli ʻo Mg a me Si i ka alumini. Eia naʻe, i ka wā o ka extrusion, noho wale ka metala ma luna o kēia mahana no ka manawa pōkole. No ka hoʻoheheʻe ʻana o Mg a me Si, pono e liʻiliʻi nā ʻāpana Mg a me Si. ʻO ka mea pōʻino, i ka wā o ka hoʻolei ʻana, hoʻokahe ʻia ʻo Mg a me Si e like me nā poloka Mg₂Si nui loa (Fig. 1a).

ʻO ka pōʻaiapili homogenization maʻamau no 6060 billets he 560 °C no 2 mau hola. I loko o kēia kaʻina hana, ʻoiai e noho ana ka billet ma luna o 530 °C no ka manawa lōʻihi, hemo ʻo Mg₂Si. Ma ka hooluolu ana, hoohuoi hou ia ma ka mahele maikai loa (Fig. 1c). Inā ʻaʻole kiʻekiʻe ka mahana homogenization, a pōkole paha ka manawa, e mau ana kekahi mau ʻāpana Mg₂Si nui. Ke hana ʻia kēia, ʻo ka hopena paʻa ma hope o ka extrusion he liʻiliʻi ka Mg a me Si, ʻaʻole hiki ke hoʻokumu i kahi kiʻekiʻe kiʻekiʻe o nā precipitates paʻakikī-e alakaʻi ana i nā waiwai mechanical i hōʻemi ʻia.

Fig. 1. Nā micrographs Optical o ka poni a me ka 2% HF-etched 6060 billets: (a) as-cast, (b) partially homogenized, (c) piha homogenized.

Ke kuleana o ka Homogenization ma Intermetallics i loko o ka hao

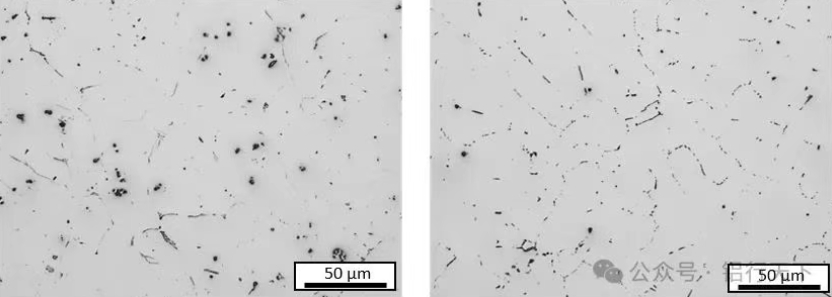

ʻOi aku ka hopena o ka hao (Fe) i ka paʻakikī haʻihaʻi ma mua o ka ikaika. I loko o 6XXX alloys, Fe hana maʻamau i ka β-phase (Al₅(FeMn)Si a i ʻole Al₈.₉(FeMn)₂Si₂) i ka wā o ka hoʻolei ʻana. ʻO kēia mau māhele he nui, angular, a keʻakeʻa i ka extrusion (i hōʻike ʻia ma Fig. 2a). I ka wā o ka homogenization, hoʻolaha nā mea koʻikoʻi (Fe, Mn, a me nā mea ʻē aʻe), a lilo nā ʻāpana angular nui i liʻiliʻi a puni (Fig. 2b).

Mai nā kiʻi optical wale nō, paʻakikī ke hoʻokaʻawale i nā pae like ʻole, a ʻaʻole hiki ke hilinaʻi i ka helu ʻana iā lākou. Ma Innoval, helu mākou i ka homogenization billet me ka hoʻohana ʻana i kā mākou ʻano ʻike hiʻohiʻona a me ka hoʻokaʻawale ʻana (FDC), e hāʻawi ana i kahi waiwai %α no nā bila. Hiki iā mākou ke loiloi i ka maikaʻi o ka homogenization.

Fig. 2. Nā micrographs Optical o nā billet (a) ma mua a (b) ma hope o ka homogenization.

ʻIke hiʻohiʻona a me ka helu ʻana (FDC).

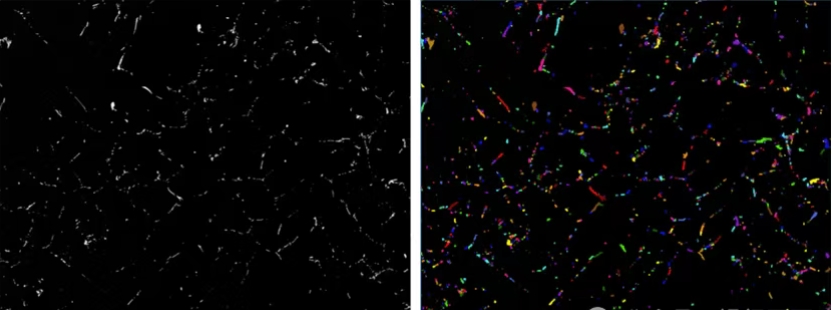

Hōʻike ka Fig. 3a i kahi laʻana i kālai ʻia e ka scanning electron microscopy (SEM). Hoʻohana ʻia kahi ʻenehana paepae hina hina e hoʻokaʻawale a ʻike i nā intermetallics, i ʻike ʻia ke keʻokeʻo ma ke kiʻi 3b. Hāʻawi kēia ʻenehana i ka nānā ʻana i nā wahi a hiki i ka 1 mm², ʻo ia hoʻi ma mua o 1000 mau hiʻohiʻona hiki ke nānā ʻia i ka manawa hoʻokahi.

Fig. 3. (a) Backscattered electron kiʻi o homogenized 6060 billet, (b) ʻike ʻia nā hiʻohiʻona pilikino mai (a).

Hoʻohui ʻāpana

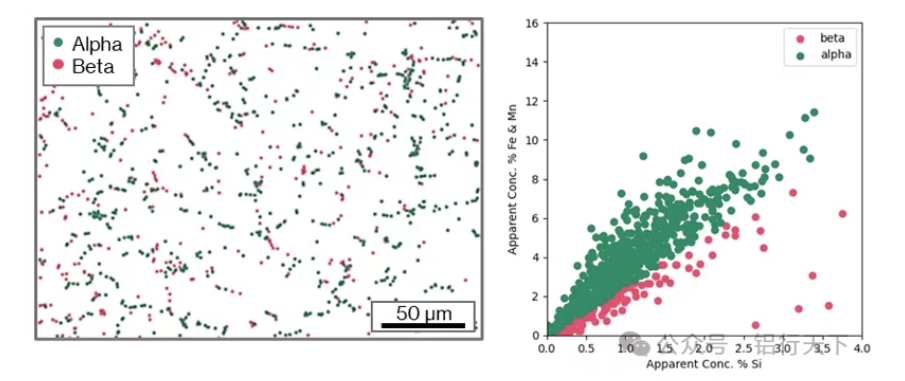

Hoʻolako ʻia ka ʻōnaehana Innoval me kahi mea ʻike maka ʻo Oxford Instruments Xplore 30 energy-dispersive X-ray (EDX). Hāʻawi kēia i ka hōʻiliʻili wikiwiki ʻana o EDX spectra mai kēlā me kēia wahi i ʻike ʻia. Mai kēia mau kiko kikoʻī, hiki ke hoʻoholo ʻia ka haku mele, a ʻike ʻia ka ratio pili Fe: Si.

Ma muli o ka Mn a i ʻole Cr maʻiʻo o ka huila, hiki ke hoʻokomo ʻia nā mea kaumaha ʻē aʻe. No kekahi 6XXX alloys (i kekahi manawa me Mn koʻikoʻi), ka (Fe+Mn): Hoʻohana ʻia ka ratio Si ma ke ʻano he kuhikuhi. A laila hiki ke hoʻohālikelike ʻia kēia mau lakio me nā mea i ʻike ʻia me ka Fe-containing intermetallics.

β-phase (Al₅(FeMn)Si a i ʻole Al₈.₉(FeMn)₂Si₂): (Fe+Mn): Si ratio ≈ 2. α-phase (Al₁₂ (FeMn)₃Si a i ʻole Al₈.₃(FeMn)₈Si : ratio 4–6 ʻO kā mākou polokalamu maʻamau e hiki iā mākou ke hoʻonohonoho i kahi paepae a hoʻokaʻawale i kēlā me kēia ʻāpana e like me α a i ʻole β, a laila palapala i ko lākou mau kūlana i loko o ka microstructure (Fig. 4). Hāʻawi kēia i kahi pākēneka o ka α i hoʻololi ʻia i loko o ka billet homogenized.

Fig. 4. (a) Palapala 'āina e hōʻike ana i nā ʻāpana α- a me β-i hoʻohui ʻia, (b) ʻāpana hoʻopuehu o (Fe+Mn):Si ratios.

He aha ka ʻikepili e haʻi mai iā mākou

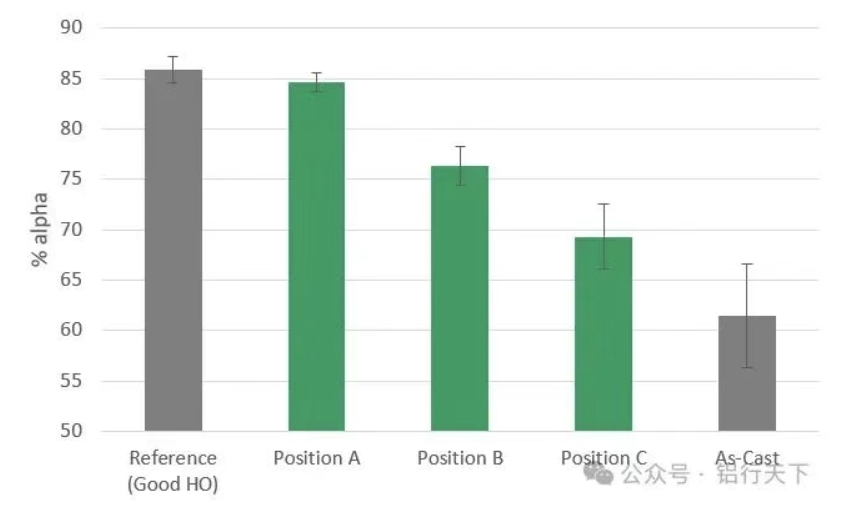

Hōʻike ka Fig. 5 i kahi laʻana o ka hoʻohana ʻana i kēia ʻike. I kēia hihia, hōʻike nā hualoaʻa i ka hoʻomehana like ʻole i loko o kahi kapuahi kikoʻī, a i ʻole ʻaʻole i hiki i ka wela hoʻonohonoho. No ka loiloi pono ʻana i ia mau hihia, pono ʻia ka billet hoʻāʻo a me nā billet kuhikuhi o ka maikaʻi ʻike ʻia. Me ka ʻole o kēia mau mea, ʻaʻole hiki ke hoʻokumu ʻia ka pae %α i manaʻo ʻia no kēlā haku mele.

Fig. 5. Hoʻohālikelike o %α ma nā ʻāpana like ʻole o kahi umu homogenization maikaʻi ʻole.

Ka manawa hoʻouna: ʻAukake-30-2025