1. Huina huila

2. Kaʻina Homogenization

390 ℃ x insulation no 1.0h + 575 ℃ x insulation no 8h, makani ikaika i ka 200 ℃ a laila hoʻoluʻu wai.

3. Hoʻolālā Metallographic

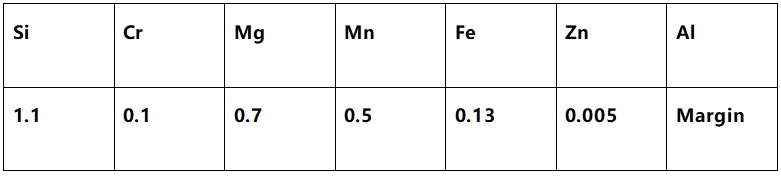

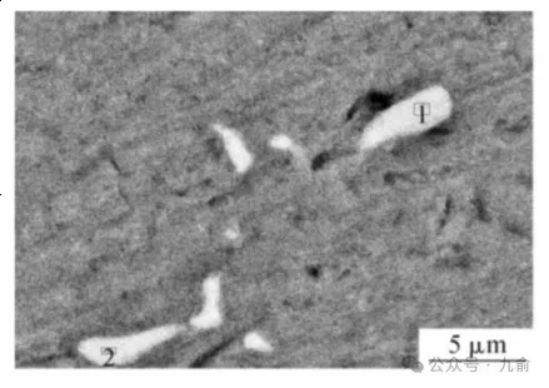

Kiʻi 1 ʻO ka hana metallographic o ke kumu o 6082 alloy ingot, i kālai ʻia e Keller reagent, me nā dendrites i kūkulu maikaʻi ʻia.

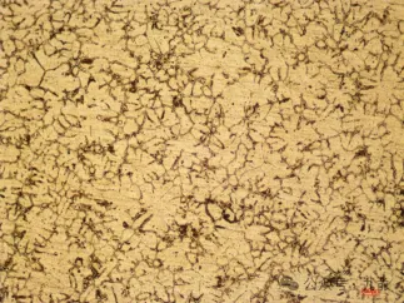

Kiʻi 2 ʻO ka hana metallographic o ke kumu o ka 6082 alloy ingot, i kālai ʻia e Keller reagent, a me ke ʻano ma hope o ka hopena paʻa.

4. Ka hopena o ka hoʻomaʻamaʻa ʻana i ka wela homogenization ma ke ʻano o ka alloy

4.1 E like me ka mea i hōʻike ʻia ma ka Figure 1, ua hoʻomohala maikaʻi ka alloy i nā dendrites i loko o ka mokuʻāina hoʻolei, a he nui ka nui o nā pae hoʻokalakupua non-equilibrium ma nā palena o ka palaoa.

4.2 No ka mea, ʻokoʻa nā helu heheʻe o nā mea like ʻole i ka wā e paʻa ai ka alloy, e alakaʻi kēia ʻano hoʻohui i ka solute ʻole i loko o ke aniani, kahi i hōʻike ʻia i ka hana ʻana o ka nui o nā pae ua i nā palena o ka palaoa.

4.3 Ma ka microstructure ma hope o ka homogenization lapaʻau (Figure 2), ka nui o precipitated phases ma ka palaoa palena ua hoemi nui ia, a me ka hua palaoa mahuahua synchronously. ʻO kēia no ka mea ua hoʻonui ʻia ka diffusion o nā mana ma lalo o ke kiʻekiʻe o ka wela, ka wehe ʻana o ka hoʻokaʻawale ʻana a me ka hoʻoheheʻe ʻana i ka pae kaulike ʻole i loko o ka ingot, a ua hoʻoheheʻe ʻia nā pūhui pūnaewele ma nā palena palaoa.

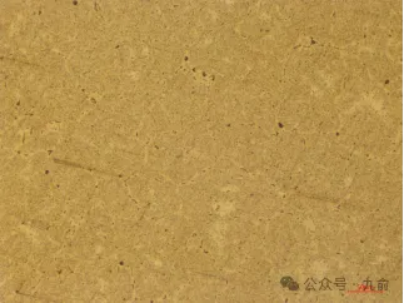

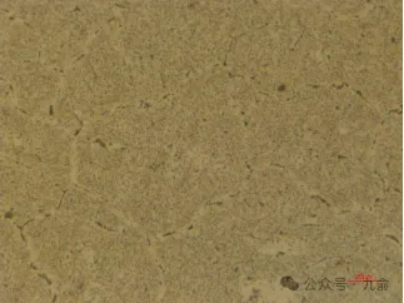

4.4 Ma o ka nānā 'ana o SEM, e like me ka mea i hō'ike 'ia ma ka FIG3, ua koho 'ia nā māhele like 'ole o ka pae precipitated no ka nānā 'ana i ka EDS, e hō'oia ana 'o ka pae ho'ohāhā 'o Al (MnFe) Si.

4.5 I ka wā o ka hoʻoheheʻe ʻia ʻana, ua hoʻokumu ʻia ka nui o ka Mn-containing phase precipitation, a mālama ʻia kahi ʻāpana i loko o ka hopena paʻa supersaturated. Ma hope o ke kiʻekiʻe-mehana a me ka lōʻihi-manawa homogenization lapaʻau, ka Mn supersaturated i loko o ka matrix precipitates ma ke ano o Mn-i loko o ka pūhui, i hoike ia e like me ka nui o ka Mn-kokohu pūhui decomposition particle precipitated i loko o ke aniani (Figure 2).

4.6 No ka mea, aia ka Mn element i loko o ka māhele precipitated, maikaʻi kona kūpaʻa wela. Me ka hoʻoikaika ʻana o ka diffusion atomic, hōʻike mālie nā ʻāpana ʻāpana Al (MnFe) Si i nā ʻano spheroidization.

Fig.3 Al(MnFe)Si māhele ma 6082 alloy

5. Ka hopena o ka ʻōnaehana ʻelemakule hoʻonā i nā waiwai mechanical

Ma hope o ka homogenization, ua hoʻoheheʻe ʻia ka pae precipitated pūnaewele ma ka palena palaoa o 6082 alloy, hiki ke hoʻomaikaʻi i nā waiwai mechanical piha o ka hāpana. I ka manawa like, ʻoi aku ka spheroidized o ka pae wela kūpaʻa paʻa Al (MnFe) Si, hiki ke ʻoi aku ka maikaʻi o nā dislocations pin. Hōʻike kēia e hoʻomaikaʻi ʻia ka hana piha o ka mea ma hope o ka hoʻomaʻamaʻa wela homogenization.

6. Ka hopena

6.1 ʻO ka 6082 alumini alumini ingot ua hoʻomohala maikaʻi ʻia nā dendrites a me ka nui o ka pūnaewele non-equilibrium precipitation phases ma nā palena palaoa.

6.2 Ma hope o ka hoʻomaʻamaʻa homogenization, ʻike ʻia ka nānā ʻana i ka microscopic ua hoʻemi nui ʻia ka nui o nā mea i hoʻoheheʻe ʻia, a ua hoʻonui ʻia ka nui o ka palaoa. ʻO ka wehe ʻana o ka hoʻokaʻawale ʻana a me ka hoʻoheheʻe ʻana o ka pae ʻole i loko o ka ingot, a ua hoʻoheheʻe ʻia nā hui pūnaewele ma nā palena o ka palaoa.

6.3 I ka hoolei ana i ka 6082 alloy, Al(MnFe)Si ua hanaia. Loaʻa i kēia māhele ua ka Mn a loaʻa iā ia ke kūpaʻa wela maikaʻi. Ke holo nei ke kaʻina hana homogenization, hōʻike mālie nā ʻāpana o ka ua i nā ʻano spheroidization. Hoʻopuehu like ʻia kēia mau ʻāpana hui Mn i loko o ka aniani.

6.4 Ma hope o ka homogenization lapaʻau, ka dissolution o ka pūnaewele precipitated māhele hōʻike i ka holoʻokoʻa hana o ka ingot holoʻokoʻa i hoʻomaikaʻi ma hope o homogenization wela lapaʻau.

Ka manawa hoʻouna: Jun-08-2025