ʻO 6063 alumini alumini no ka Al-Mg-Si series heat-treatable alumini alloy. Loaʻa iā ia ka hana hoʻoheheʻe extrusion maikaʻi, ke kūpaʻa corrosion maikaʻi a me nā waiwai mechanical piha. Hoʻohana nui ʻia ia i ka ʻoihana automotive no ka maʻalahi o ka waihoʻoluʻu oxidation. Me ka wikiwiki o ke ʻano o nā kaʻa māmā, ua hoʻonui hou ʻia ka noi ʻana o 6063 alumini alumini extrusion mea i loko o ka ʻoihana kaʻa.

Hoʻopili ʻia ka microstructure a me nā waiwai o nā mea extruded e nā hopena i hui pū ʻia o ka wikiwiki extrusion, extrusion temperature a me extrusion ratio. I waena o lākou, ʻo ka ratio extrusion e hoʻoholo nui ʻia e ka extrusion pressure, hana pono a me nā lako hana. Ke liʻiliʻi ka lakio extrusion, liʻiliʻi ka deformation alloy a ʻaʻole maopopo ka microstructure refinement; ʻO ka hoʻonui ʻana i ka ratio extrusion hiki ke hoʻomaʻemaʻe nui i nā kīʻaha, wāwahi i ka lua o ka lua, loaʻa kahi microstructure like ʻole, a hoʻomaikaʻi i nā ʻano mechanical o ka alloy.

ʻO 6061 a me 6063 alumini alumini e hana i ka recrystallization ikaika i ka wā o ke kaʻina extrusion. Ke hoʻomau ka mahana extrusion, e like me ka piʻi ʻana o ka ratio extrusion, emi ka nui o ka palaoa, hoʻopuehu maikaʻi ʻia ka pae hoʻoikaika, a hoʻonui ʻia ka ikaika tensile a me ka elongation o ka alloy; akā naʻe, i ka piʻi ʻana o ka lākiō extrusion, piʻi pū ka ikaika extrusion i koi ʻia no ke kaʻina extrusion, e hoʻonui ana i ka hopena wela, e piʻi ai ka mahana o loko o ka huila, a me ka hana o ka huahana. Ke noiʻi nei kēia hoʻokolohua i ka hopena o ka ratio extrusion, ʻoi aku ka nui extrusion ratio, ma ka microstructure a me nā waiwai mechanical o 6063 alumini alumini.

1 Nā mea hoʻokolohua a me nā ʻano hana

ʻO ka mea hoʻokolohua he 6063 alumini alumini, a ua hōʻike ʻia ke ʻano kemika ma ka Papa 1. ʻO ka nui kumu o ka ingot ʻo Φ55 mm × 165 mm, a ua hana ʻia i kahi billet extrusion me ka nui o Φ50 mm × 150 mm ma hope o ka hoʻomaʻamaʻa homogenization ma 560 ℃ no 6 mau hola. Hoʻomoʻa ʻia ka billet i 470 ℃ a mālama ʻia me ka mahana. ʻO ka mahana wela o ka pahu extrusion he 420 ℃, a ʻo ka mahana preheating o ka mold he 450 ℃. Ke hoʻololi ʻole ka wikiwiki extrusion (extrusion rod neʻe wikiwiki) V = 5 mm / s, 5 mau pūʻulu o nā hoʻokolohua lākiō extrusion ʻokoʻa i lawe ʻia, a ʻo nā lākiō extrusion R he 17 (e pili ana i ke anawaena die hole D = 12 mm), 25 (D = 10 mm), 39 (D = 8 mm), 69 (D = 8 mm), 69 (D = 156 mm), a me 69 (D = 156 mm).

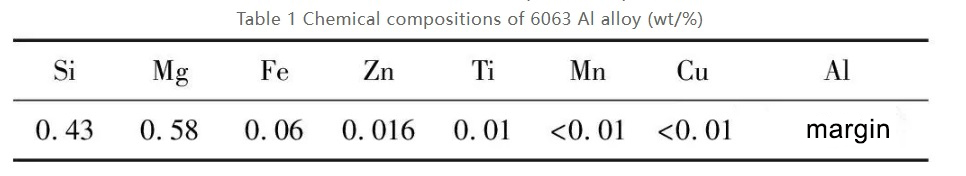

Papa 1 Nā haku mele ʻana o 6063 Al alloy (wt/%)

Ma hope o ka wili ʻana i ka pepa a me ka polishing mechanical, ua kālai ʻia nā laʻana metallographic me ka HF reagent me ka hapa nui o 40% no kahi o 25 s, a ua nānā ʻia ke ʻano metala o nā laʻana ma kahi microscope optical LEICA-5000. Ua ʻoki ʻia kahi laʻana hoʻohālikelike kikokikona me ka nui o 10 mm × 10 mm mai ke kikowaena o ka ʻāpana longitudinal o ke koʻokoʻo i hoʻokuʻu ʻia, a ua hana ʻia ka mīkini wili a me ka etching no ka wehe ʻana i ke koʻikoʻi o ka ʻili. Ua ana ʻia nā kiʻi pole piha ʻole o nā mokulele aniani ʻekolu {111}, {200}, a me {220} o ka hāpana e ka X′Pert Pro MRD X-ray diffraction analyzer o PANalytical Company, a ua hoʻoponopono ʻia ka ʻikepili kikokikona e X′Pert Data View a me X′Pert Texture lako polokalamu.

Ua laweʻia ka'ōpana tensile o ka mea hoʻoheheʻeʻia mai ke kikowaena o ka ingot, a uaʻokiʻia keʻano o ka tensile ma kaʻaoʻao extrusion ma hope o ka extrusion. ʻO Φ4 mm × 28 mm ka nui o ke ana. Ua hoʻokō ʻia ka hoʻāʻo tensile me ka mīkini hoʻāʻo ʻenehana honua SANS CMT5105 me ka helu tensile o 2 mm / min. Ua helu ʻia ka waiwai maʻamau o nā ʻano mea maʻamau ʻekolu ma ke ʻano he ʻikepili waiwai mechanical. Ua ʻike ʻia ka morphology haʻihaʻi o nā specimens tensile me ka hoʻohana ʻana i kahi microscope electron scanning haʻahaʻa (Quanta 2000, FEI, USA).

2 Nā hualoaʻa a me ke kūkākūkā

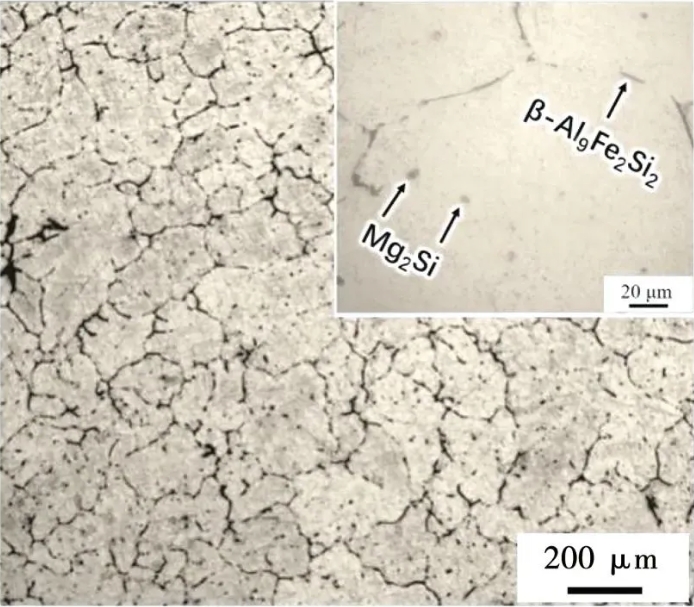

Hōʻike ka Figure 1 i ka microstructure metallographic o ka as-cast 6063 alumini alumini ma mua a ma hope o ka mālama homogenization. E like me ka mea i hōʻike ʻia ma ka Figure 1a, ʻokoʻa ka nui o nā kīʻaha α-Al i loko o ka microstructure as-cast, nui ka nui o nā ʻāpana reticular β-Al9Fe2Si2 e hōʻiliʻili ma nā palena o ka palaoa, a aia ka nui o nā ʻāpana Mg2Si granular i loko o ka palaoa. Ma hope o ka homogenized o ka ingot ma 560 ℃ no 6 mau hola, ua hoʻoheheʻe ʻia ka pae eutectic non-equilibrium ma waena o nā dendrites alloy, ua hoʻoheheʻe ʻia nā mea ala i loko o ka matrix, ua like ka microstructure, a ʻo ka nui o ka palaoa ma kahi o 125 μm (Figure 1b).

Ma mua o ka homogenization

Ma hope o ka hoʻohana ʻana i ka mālama ʻana ma 600 ° C no 6 mau hola

Fig.1 Metallographic hana o 6063 alumini alumini ma mua a ma hope o homogenization lapaʻau

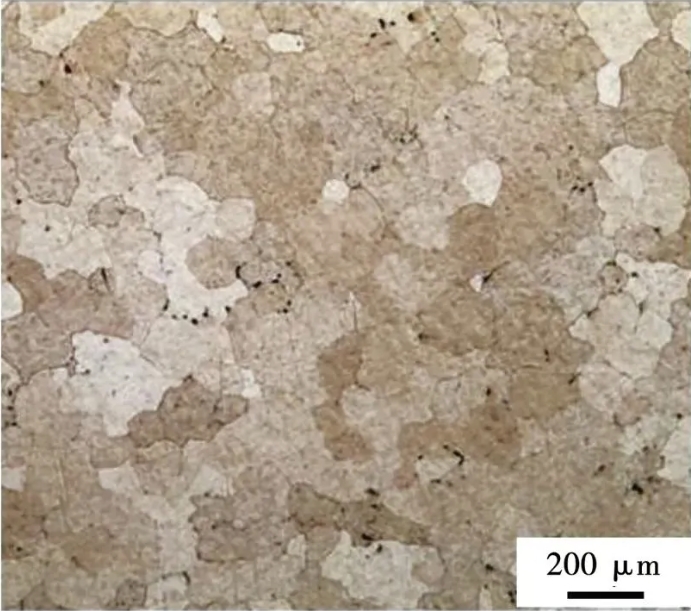

Hōʻike ka helu 2 i ke ʻano o 6063 mau pahu alumini alumini me nā lākiō extrusion like ʻole. E like me ka mea i hōʻike ʻia ma ka Figure 2, ʻoi aku ka maikaʻi o ka maikaʻi o ka 6063 alumini alumini kaola i hoʻokuʻu ʻia me nā lākiō extrusion ʻē aʻe, ʻoi aku ka maikaʻi o ka hoʻonui ʻia ʻana o ka lākiō extrusion i 156 (e pili ana i ka wikiwiki o ka puka extrusion o 48 m / min), ʻaʻohe mau hemahema extrusion e like me nā māwae a me ka ʻili ʻana ma ka ʻili o ka pā, e hōʻike ana i ka extrusion extrusion maikaʻi ma lalo o ka extrusion kiʻekiʻe. a nui extrusion ratio.

Fig.2 Na hiʻohiʻona o 6063 alumini alumini koʻokoʻo me nā lākiō extrusion likeʻole

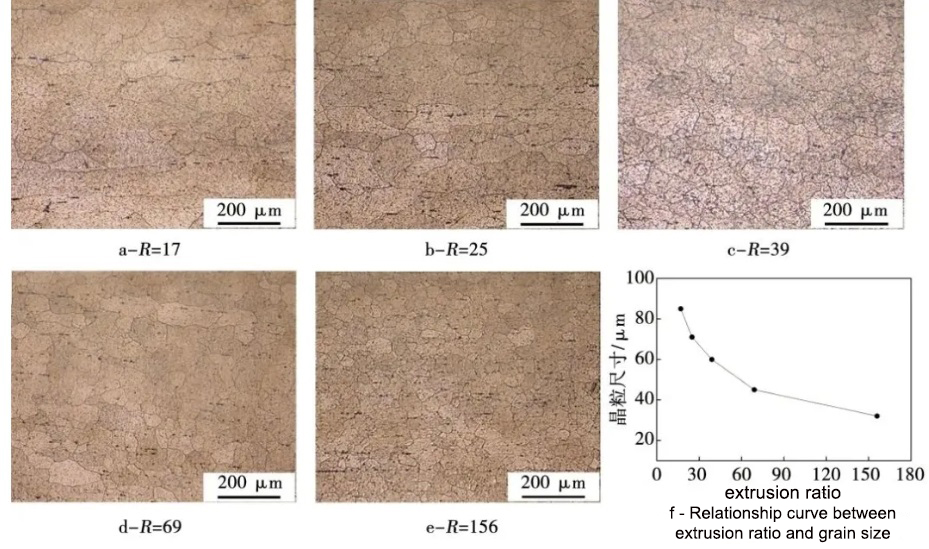

Hōʻike ka Figure 3 i ka microstructure metallographic o ka ʻāpana longitudinal o ka pahu alumini alumini 6063 me nā lākiō extrusion like ʻole. ʻO ke ʻano o ka palaoa o ka pā me nā lākiō extrusion like ʻole e hōʻike ana i nā degere like ʻole o ka elongation a i ʻole ka hoʻomaʻemaʻe. I ka manawa o ka extrusion ratio he 17, ua elongated ka hua kumu mua ma ka extrusion kuhikuhi, hele pu me ka hookumuia ana o ka uuku helu o recrystallized hua, akā, ua mau ka palaoa, me ka awelika o ka palaoa ma kahi o 85 μm (Figure 3a); i ka manawa o ka extrusion ratio he 25, ua oi aku ka slender o na hua, ka heluna o ka recrystallized hua, a me ka awelika o ka palaoa e emi iho ma kahi o 71 μm (Figure 3b); inā he 39 ka lākiō extrusion, koe wale no ka liʻiliʻi o nā kīʻaha deformed, ua haku ʻia ka microstructure me nā huaʻai recrystallized equiaxed o ka nui ʻole, me ka nui o ka palaoa ma kahi o 60 μm (Figure 3c); i ka wā o ka extrusion lākiō he 69, ka dynamic recrystallization kaʻina hana i basically hoʻopau, ka coarse kumu mua i hoʻololi loa 'ia i uniformly structured recrystallized hua, a me ka awelika o ka palaoa i hoʻomaʻemaʻeʻia ma kahi o 41 μm (Figure 3d); i ka manawa o ka extrusion ratio he 156, me ka holomua piha o ka dynamic recrystallization kaʻina hana, ka microstructure ua oi like, a me ka hua palaoa ua hoʻomaʻemaʻe loa i ka 32 μm (Figure 3e). Me ka piʻi ʻana o ka ratio extrusion, ʻoi aku ka maikaʻi o ke kaʻina hana recrystallization, ʻoi aku ka like o ka microstructure alloy, a hoʻomaʻemaʻe nui ʻia ka nui o ka palaoa (Figure 3f).

Fig.3 ʻO ke kinona metallographic a me ka nui o ka palaoa o ka ʻāpana longitudinal o 6063 mau koʻokoʻo alumini alumini me nā lākiō extrusion like ʻole.

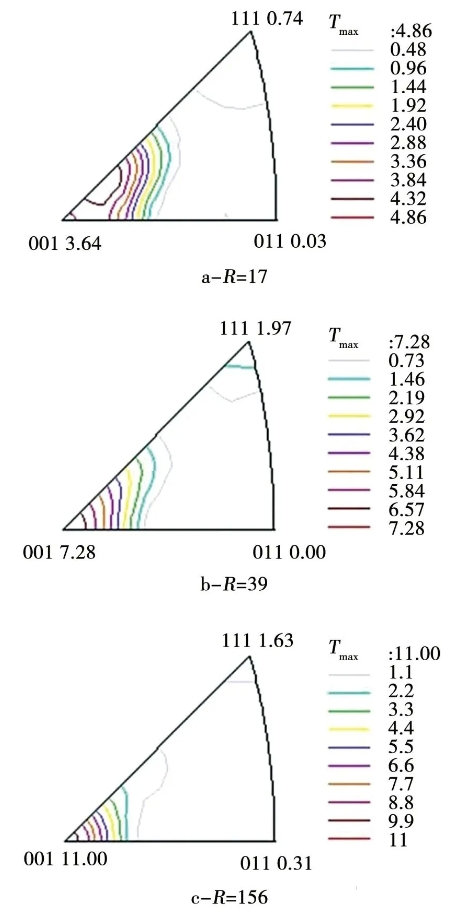

Hōʻike ka Figure 4 i nā kiʻi pole inverse o 6063 mau pahu alumini alumini me nā lākiō extrusion like ʻole ma ka ʻaoʻao extrusion. Hiki ke ʻike ʻia ʻo nā microstructures o nā pahu hao me nā lākiō extrusion like ʻole e hoʻopuka i kahi ʻano makemake. Ke 17 ka lakio extrusion, ua hoʻokumu ʻia kahi ʻano nāwaliwali <115>+<100> (Figure 4a); inā he 39 ka lākiō extrusion, ʻoi aku ka ikaika o nā ʻāpana kikokikona <100> a me kahi liʻiliʻi o ka nāwaliwali <115> kikokikona (Figure 4b); inā he 156 ka lakio extrusion, ʻo nā ʻāpana kikokikona ke ʻano <100> me ka hoʻonui nui ʻana i ka ikaika, aʻo ka <115> e nalowale ana (Figure 4c). Ua hōʻike ʻia nā haʻawina ʻo nā metala cubic i hoʻohālikelike ʻia i ke alo he <111> a me <100> mau ʻano uea i ka wā extrusion a me ke kaha kiʻi. Ke hoʻokumu ʻia ke ʻano, hōʻike ʻia ka anisotropy maʻemaʻe o ka lumi wela o ka hale. Ke piʻi aʻe nei ka ikaika kikokikona me ka piʻi ʻana o ka lākiō extrusion, e hōʻike ana i ka nui o nā kīʻaha i kekahi ʻaoʻao aniani e like me ke kuhikuhi extrusion i loko o ka alloy e piʻi mālie, a piʻi ka ikaika tensile longitudinal o ka alloy. ʻO nā mea hoʻoikaika ikaika o 6063 alumini alumini wela extrusion mea hoʻoikaika i ka palaoa maikaʻi, dislocation ka hoʻoikaika ʻana, ka hoʻoikaika kino, a me nā mea ʻē aʻe.

Fig.4 Hoʻohuli pole kiʻi o 6063 alumini koʻokoʻo aluminika me nā lākiō extrusion like ʻole ma ka ʻaoʻao extrusion.

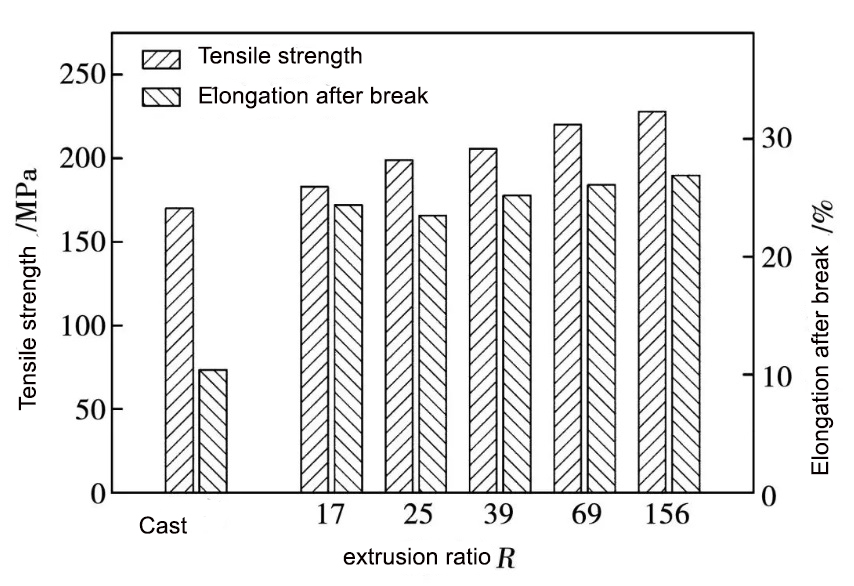

He kiʻi 5 ka histogram o nā waiwai tensile o 6063 alumini alumini ma hope o ka deformation ma nā ʻano extrusion like ʻole. ʻO 170 MPa ka ikaika tensile o ka alloy cast a ʻo ka elongation he 10.4%. ʻO ka ikaika tensile a me ka elongation o ka alloy ma hope o ka extrusion e hoʻomaikaʻi maikaʻi ʻia, a ʻo ka ikaika tensile a me ka elongation e piʻi mālie me ka piʻi ʻana o ka ratio extrusion. Ke hiki i ka ratio extrusion he 156, hiki i ka ikaika tensile a me ka elongation o ka alloy i ka waiwai kiʻekiʻe, ʻo ia ka 228 MPa a me 26.9%, kēlā me kēia, ma kahi o 34% kiʻekiʻe ma mua o ka ikaika tensile o ka alloy cast a ma kahi o 158% kiʻekiʻe ma mua o ka elongation. ʻO ka ikaika tensile o 6063 alumini alumini i loaʻa e ka nui extrusion ratio kokoke i ka tensile ikaika waiwai (240 MPa) i loaʻa e 4-pass equal channel angular extrusion (ECAP), i ʻoi aku ka kiʻekiʻe ma mua o ka waiwai tensile ikaika (171.1 MPa) i loaʻa e 1-pass ECAP extrusion o 6063 alumini alumini. Hiki ke ʻike ʻia he nui ka extrusion ratio hiki ke hoʻomaikaʻi i nā waiwai mechanical o ka alloy i kekahi ʻano.

ʻO ka hoʻonui ʻana i nā waiwai mechanical o ka alloy ma ka extrusion ratio ka mea nui mai ka hoʻoikaika ʻana i ka palaoa. I ka piʻi ʻana o ka ratio extrusion, hoʻomaʻemaʻe ʻia nā kīʻaha a piʻi ka dislocation density. Hiki i nā palena o ka palaoa i kēlā me kēia ʻāpana ke hoʻoikaika pono i ka neʻe ʻana o nā dislocations, i hui pū ʻia me ka neʻe like ʻana a me ka hoʻopili ʻana o nā dislocations, a laila e hoʻomaikaʻi ai i ka ikaika o ka alloy. ʻO ka ʻoi aku ka maikaʻi o ka palaoa, ʻoi aku ka ʻoi aku o ka tortuous o nā palena o ka palaoa, a hiki ke hoʻopuehu ʻia ka deformation plastic i loko o nā kīʻaha hou aʻe, ʻaʻole kūpono i ka hana ʻana o nā māwae, e waiho wale i ka hoʻolaha ʻana o nā māwae. Hiki ke hoʻonui i ka ikehu i ka wā o ka haʻihaʻi, e hoʻomaikaʻi ai i ka plasticity o ka alloy.

Fig.5 Nā waiwai tensile o 6063 alumini alumini ma hope o ka hoʻolei ʻana a me ka extrusion

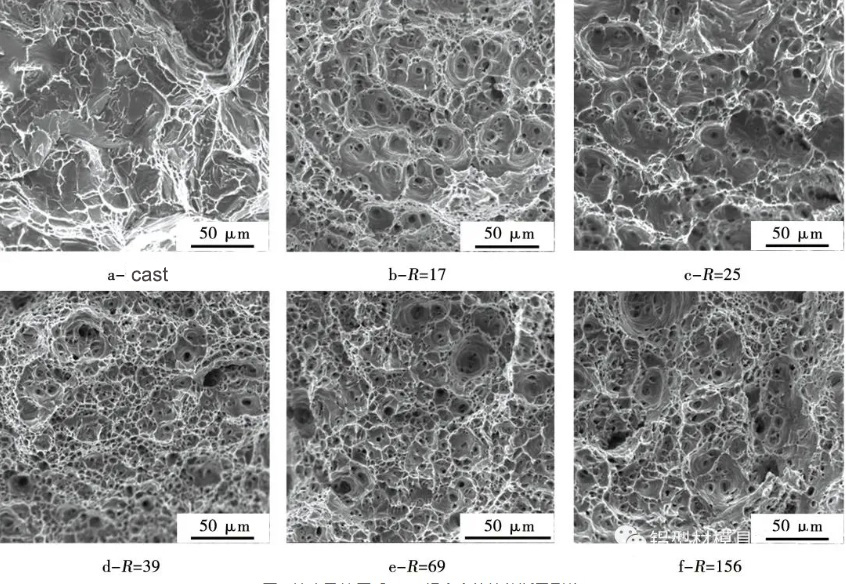

Hōʻike ʻia ka morphology haʻihaʻi tensile o ka huila ma hope o ka deformation me nā lākiō extrusion like ʻole ma ka Figure 6. ʻAʻole i ʻike ʻia nā dimples ma ka morphology haʻihaʻi o ka hāpana as-cast sample (Figure 6a), a ʻo ka haʻihaʻi i haku ʻia me nā wahi pālahalaha a me nā ʻaoʻao haehae, e hōʻike ana ʻo ke ʻano o ka tensile fracture alloy ka mea nui o ka ʻili. Ua loli nui ka morphology o ka haʻihaʻi o ka huila ma hope o ka extrusion, a ua hoʻokumu ʻia ka haʻihaʻi me ka nui o nā dimples equiaxed, e hōʻike ana ua hoʻololi ke ʻano o ka haʻihaʻi o ka huila ma hope o ka extrusion. Ke liʻiliʻi ka ratio extrusion, pāpaʻu nā dimples a nui ka nui o ka dimple, a ʻaʻole like ka puʻunaue; i ka piʻi ʻana o ka ratio extrusion, piʻi ka helu o nā dimples, ʻoi aku ka liʻiliʻi o ka nui o ka dimple a ʻo ka hāʻawi like ʻana (Figure 6b~f), ʻo ia hoʻi, ʻoi aku ka maikaʻi o ka palaki, ʻoi aku ka maikaʻi me nā hopena hoʻāʻo ʻenehana ma luna.

3 Ka hopena

I loko o kēia hoʻokolohua, ʻike ʻia nā hopena o nā lākiō extrusion like ʻole i ka microstructure a me nā waiwai o 6063 alumini alumini ma lalo o ke ʻano o ka nui o ka billet, ka mahana wela ingot a me ka wikiwiki extrusion i hoʻololi ʻole ʻia. ʻO nā hopena penei:

1) Hana ʻia ka hoʻihoʻi hou ʻana i ka 6063 alumini alumini i ka wā extrusion wela. Me ka piʻi ʻana o ka lākiō extrusion, hoʻomaʻemaʻe mau ʻia nā kīʻaha, a ua hoʻololi ʻia nā kīʻaha elongated ma ke ala extrusion i loko o nā ʻāpana recrystallized equiaxed, a ua hoʻonui mau ʻia ka ikaika o <100> wire texture.

2) Ma muli o ka hopena o ka hoʻoikaika ʻana i ka palaoa maikaʻi, hoʻomaikaʻi ʻia nā ʻano mechanical o ka alloy me ka piʻi ʻana o ka ratio extrusion. I loko o ka laulā o nā ʻāpana hoʻāʻo, i ka wā o ka extrusion ratio he 156, ʻo ka ikaika tensile a me ka elongation o ka alloy e hiki i nā helu kiʻekiʻe o 228 MPa a me 26.9%, kēlā me kēia.

Fig.6 Nā morphologies haʻihaʻi tensile o 6063 alumini alumini ma hope o ka hoʻolei ʻana a me ka extrusion.

3) Hoʻokumu ʻia ka morphology haʻihaʻi o ka specimen as-cast me nā wahi palahalaha a me nā ʻaoʻao waimaka. Ma hope o ka extrusion, ua haku ʻia ka haʻihaʻi me ka nui o nā dimples equiaxed, a ua hoʻololi ʻia ke ʻano haʻihaʻi mai ka haʻihaʻi a i ka haʻi ductile.

Ka manawa hoʻouna: Nov-30-2024