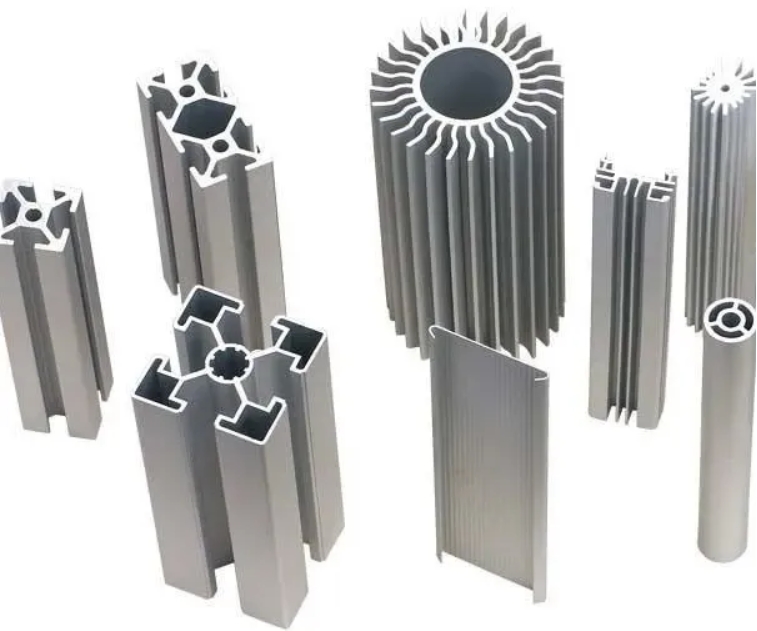

He mea maʻamau ka alumini no ka extrusion a me ka hoʻohālikelike ʻana i nā profiles no ka mea he mau ʻano mechanical i kūpono ia no ka hana ʻana a me ka hoʻohua ʻana i nā metala mai nā ʻāpana billet. ʻO ka ductility kiʻekiʻe o ka alumini ka mea hiki ke hana maʻalahi i ka metala i loko o nā ʻāpana like ʻole me ka hoʻohana ʻole ʻana i ka nui o ka ikehu i ka mīkini a i ʻole ke kaʻina hana, a ʻo ka alumini hoʻi he wahi heheʻe ma kahi o ka hapalua o ke kila maʻamau. ʻO kēia mau mea ʻelua ke manaʻo nei he haʻahaʻa haʻahaʻa ke kaʻina hana extrusion aluminum profile, e hōʻemi ana i nā kumukūʻai mea hana a me ka hana. ʻO ka mea hope loa, loaʻa i ka alumini ka ikaika kiʻekiʻe i ka ratio paona, e lilo ia i koho maikaʻi loa no nā noi ʻoihana.

Ma ke ʻano he hopena o ke kaʻina extrusion, hiki ke ʻike ʻia nā laina maikaʻi a kokoke i ʻike ʻole ʻia ma ka ʻili o ka ʻaoʻao. ʻO kēia ka hopena o ka hoʻokumu ʻana i nā mea kōkua i ka wā extrusion, a hiki ke kuhikuhi ʻia nā lāʻau lapaʻau hou e wehe i kēia mau laina. No ka hoʻomaikaʻi ʻana i ka pau ʻana o ka ʻaoʻao o ka ʻaoʻao, hiki ke hana ʻia kekahi mau hana lapaʻau lua e like me ka wili maka ma hope o ke kaʻina hana extrusion. Hiki ke kuhikuhi ʻia kēia mau hana mīkini no ka hoʻomaikaʻi ʻana i ka geometry o ka ʻili e hoʻomaikaʻi i ka ʻaoʻao ʻāpana ma o ka hōʻemi ʻana i ka ʻōpala āpau o ka ʻaoʻao extruded. Hōʻike pinepine ʻia kēia mau lāʻau lapaʻau i nā noi kahi e pono ai ke hoʻonohonoho pololei ʻana o ka ʻāpana a i ʻole kahi e hoʻopaʻa paʻa ʻia ai nā papa male.

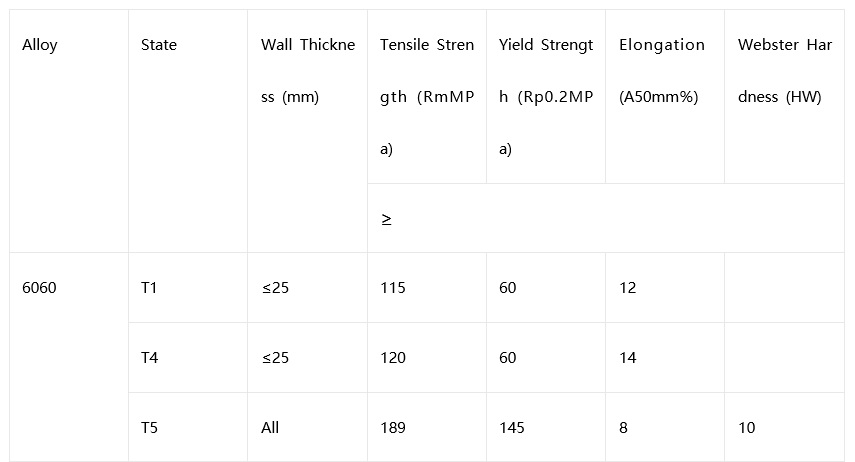

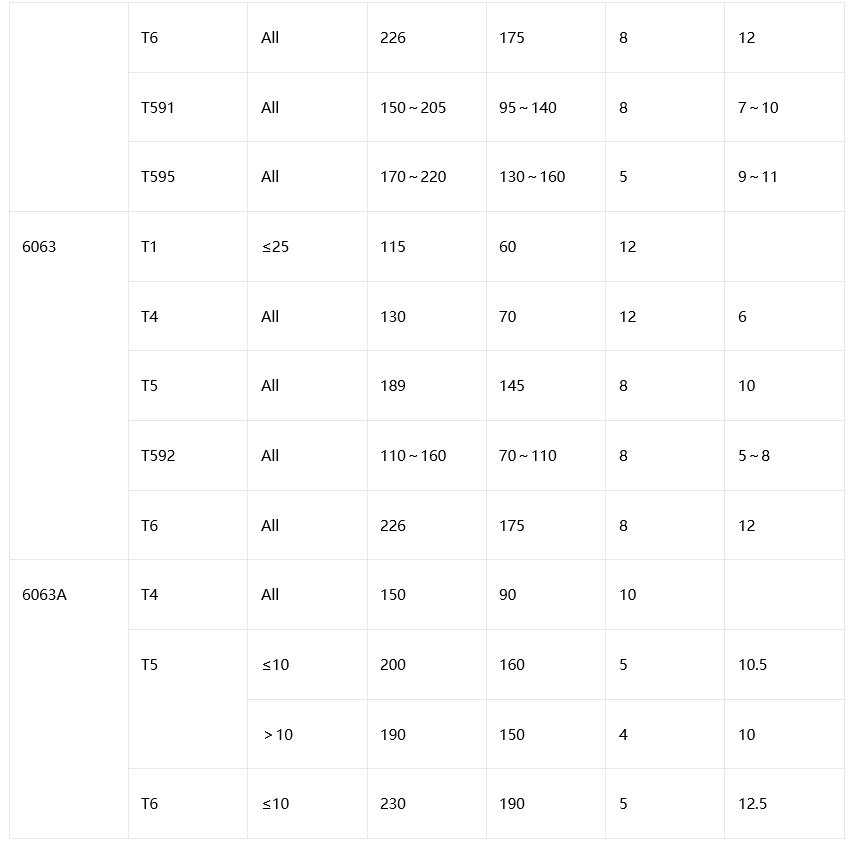

ʻIke pinepine mākou i ke kolamu waiwai i kaha ʻia me 6063-T5/T6 a i ʻole 6061-T4, a me nā mea ʻē aʻe. ʻO ka 6063 a i ʻole 6061 ma kēia māka ʻo ia ka brand o ka profile aluminika, a ʻo T4 / T5 / T6 ke kūlana o ka ʻike alumini. No laila he aha ka ʻokoʻa ma waena o lākou?

No ka laʻana: ʻO ka waiho wale ʻana, ʻoi aku ka ikaika o ka 6061 alumini profile a me ka hana ʻoki ʻana, me ka paʻakikī kiʻekiʻe, ka weldability maikaʻi a me ke kūpaʻa corrosion; ʻOi aku ka maikaʻi o ka palaki 6063 aluminika, hiki ke hoʻokō i ka mea i kiʻekiʻe kiʻekiʻe, a i ka manawa like me ka ikaika tensile kiʻekiʻe a me ka ikaika o ka hāʻawi ʻana, e hōʻike ana i ka ʻoi aku ka maikaʻi o ka haʻihaʻi ʻana, a he ikaika kiʻekiʻe, ʻaʻahu ke kūpaʻa, ka pale ʻana a me ke kūpaʻa wela kiʻekiʻe.

Kūlana T4:

hoʻoponopono hoʻoponopono + ʻelemakule maoli, ʻo ia hoʻi, ua maʻalili ʻia ka ʻaoʻao alumini ma hope o ka hoʻokuʻu ʻia ʻana mai ka extruder, akā ʻaʻole i ʻelemakule i ka umu ʻelemakule. ʻO ka ʻaoʻao alumini ʻaʻole i ʻelemakule he haʻahaʻa haʻahaʻa haʻahaʻa a me ka deformability maikaʻi, kūpono ia no ka kuʻi hope a me ka hana deformation ʻē aʻe.

Kūlana T5:

ka hoʻoponopono hoʻoponopono + incomplete artificial aging, ʻo ia hoʻi, ma hope o ka hoʻoheheʻe ʻana o ka ea ma hope o ka extrusion, a laila hoʻoneʻe ʻia i ka umu ʻelemakule e mālama i ka mahana ma kahi o 200 degere no 2-3 mau hola. ʻO ka alumini i kēia moku'āina he paʻakikī kiʻekiʻe a me kahi deformability. ʻO ia ka mea maʻamau i hoʻohana ʻia i nā paia pale.

Kūlana T6:

ka hoʻoponopono hoʻoponopono + piha ʻana i ka ʻelemakule, ʻo ia hoʻi, ma hope o ka hoʻoheheʻe ʻana i ka wai ma hope o ka extrusion, ʻoi aku ka kiʻekiʻe o ka ʻelemakule ma mua o ka T5 wela, a ʻoi aku ka lōʻihi o ka manawa insulation, i mea e hoʻokō ai i kahi kūlana paʻakikī kiʻekiʻe.

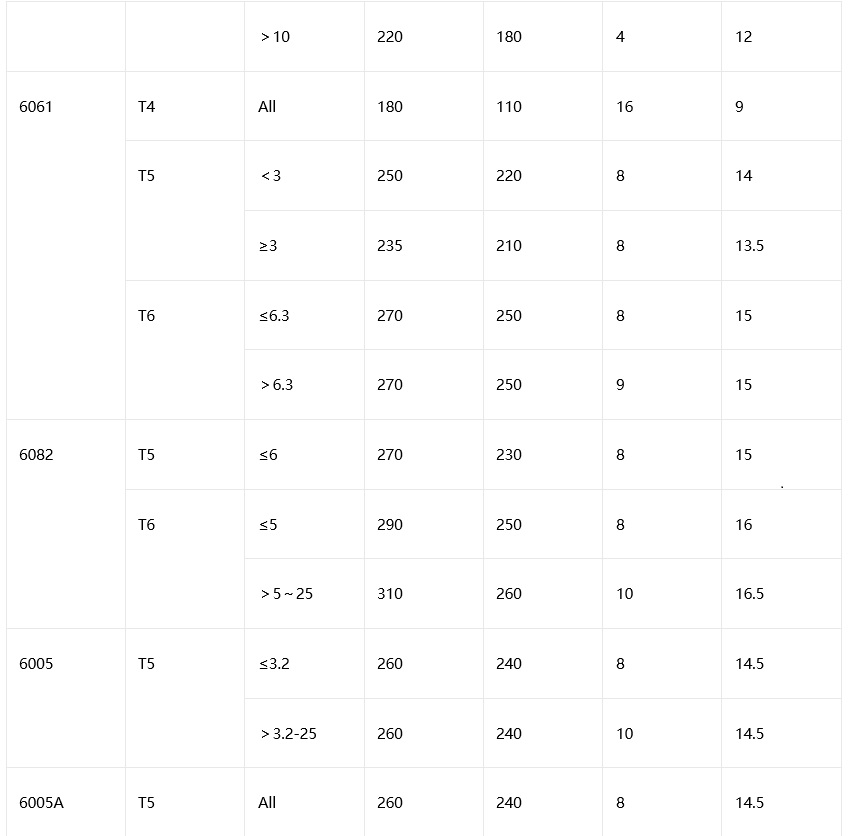

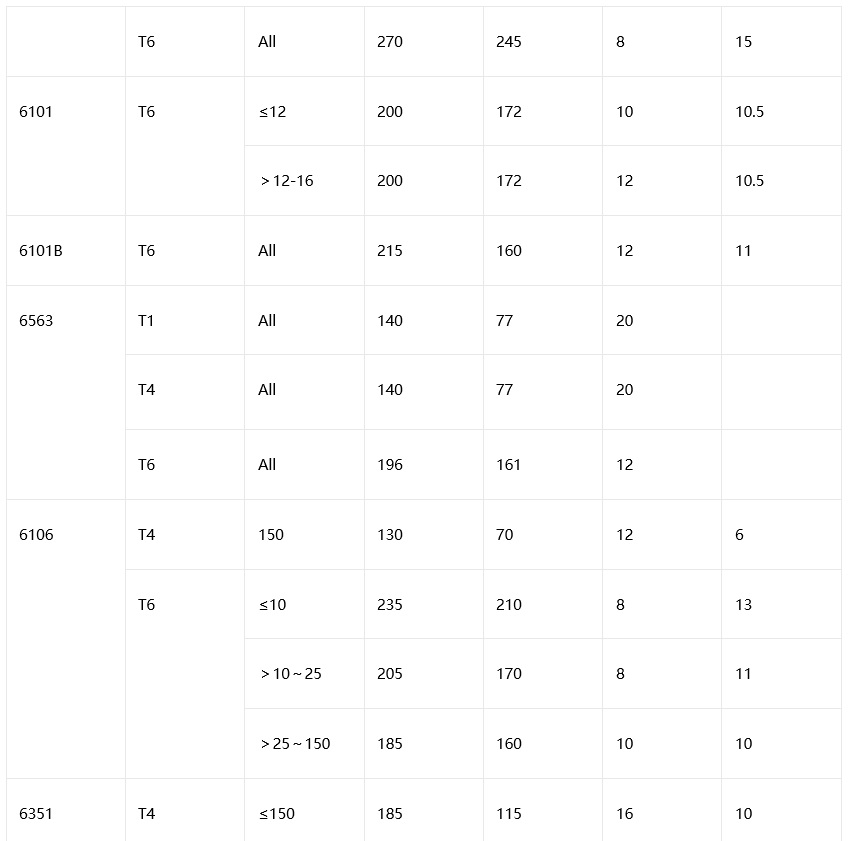

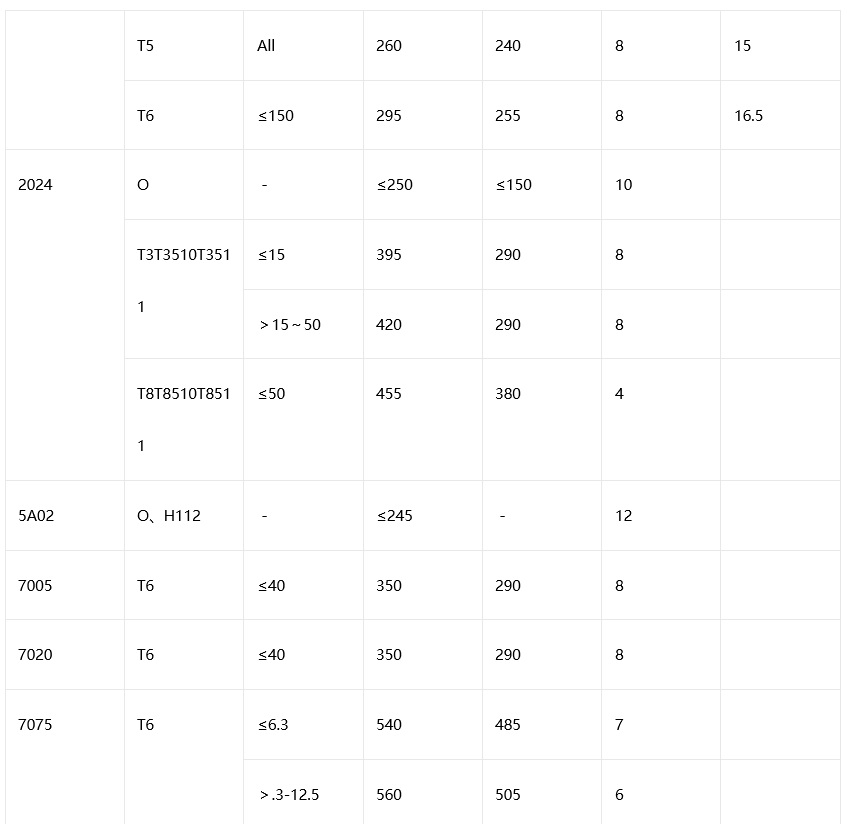

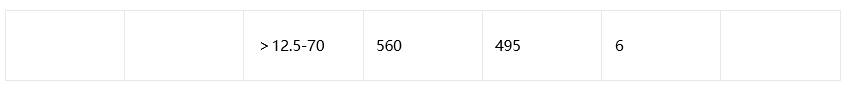

ʻO nā waiwai mechanical o nā profile alumini o nā mea like ʻole a me nā mokuʻāina ʻē aʻe i kikoʻī ʻia ma ka papa ma lalo nei:

Ka ikaika hana:

ʻO ia ka palena o nā mea metala ke hāʻawi lākou, ʻo ia hoʻi, ke koʻikoʻi e kūʻē i ka micro plastic deformation. No nā mea metala me ka ʻike ʻole o ka hua, ʻo ke koʻikoʻi e hoʻopuka ai i ke koena deformation he 0.2% i kuhikuhi ʻia e like me kona palena hua, i kapa ʻia ʻo conditional yield limit a i ʻole yield strength. ʻO nā ikaika o waho i ʻoi aku ma mua o kēia palena e hāʻule mau loa nā ʻāpana a ʻaʻole hiki ke hoʻihoʻi ʻia.

Ka ikaika tensile:

Ke hāʻawi ʻia ka alumini i kekahi ʻano, hiki i kona hiki ke pale i ka deformation e hoʻonui hou ʻia ma muli o ka hoʻonohonoho hou ʻana o nā kīʻaha kūloko. ʻOiai e ulu wikiwiki ana ka deformation i kēia manawa, hiki ke hoʻonui wale me ka piʻi ʻana o ke koʻikoʻi a hiki i ke koʻikoʻi i ka waiwai nui. Ma hope o kēlā, ua hoʻemi nui ʻia ka hiki o ka profile ke kūʻē i ka deformation, a hiki i kahi deformation plastic nui ma kahi nāwaliwali loa. ʻO ka ʻāpana keʻa o ka mea hōʻike maʻaneʻi e emi koke, a hiki ke ʻāʻī a haki.

ʻO ka paʻakikī pūnaewele:

ʻO ke kumu kumu o ka paʻakikī Webster ʻo ia ka hoʻohana ʻana i kahi nila kaomi hoʻopaʻa ʻia o kekahi ʻano e kaomi i ka ʻili o ka hāpana ma lalo o ka ikaika o ka punawai maʻamau, a wehewehe i kahi hohonu o 0.01MM ma ke ʻano he ʻāpana paʻakikī Webster. ʻO ka paʻakikī o ka mea i hoʻohālikelike ʻia me ka hohonu o ke komo ʻana. ʻOi aku ka pāpaʻu o ke komo ʻana, ʻoi aku ka kiʻekiʻe o ka paʻakikī, a ʻo ia hoʻi.

ʻO ka hoʻololi ʻana i ka palaki:

He ʻano deformation kēia ʻaʻole hiki ke hoʻihoʻi iā ia iho. Ke hoʻouka ʻia nā mea ʻenekinia a me nā ʻāpana ma waho aʻe o ka laulā deformation elastic, e kū mai ka deformation mau, ʻo ia hoʻi, ma hope o ka lawe ʻia ʻana o ka ukana, hiki ke hoʻololi ʻole ʻia a i ʻole ke koena deformation, ʻo ia ka deformation plastic.

Ka manawa hoʻouna: Oct-09-2024